PTA Welding System

-

DXB-NC301 Cantilever plasma surfacing system

The walking mechanism is driven by imported linear guide rail, precision worm gear reducer and stepping motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

DSL-LC401 Double cone injection molding machine barrel inner hole cladding machine

The mechanical walking mechanism is driven by imported linear guide rail, precision worm gear reducer and stepping motor. The whole machine has small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

Welding roller carrier adopts double power, two wheels rotate at the same time.The driven wheel can be adjusted up and down, and can slide back and forth to meet the needs of all kinds of barrel products with different lengths.

-

FB-200P Automatic plasma welding machine for valve

The mechanical walking structure adopts imported linear guide rail, precision worm gear reducer and stepper motor drive walking. The whole machine has small transmission clearance, high rigidity, stable and reliable operation, and convenient integration.

-

DZB-NC401 Automatic plasma cladding surfacing system for middle groove

The mechanical walking mechanism is driven by imported linear guide rail, precision worm gear reducer and stepping motor. The whole machine has small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

DH3-HV1700-B06 manipulator positioner

Picture Equipment features HV1700 welding manipulator adopts imported linear guide rail, precision worm gear reducer and stepping motor to drive, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration. Hbt-3 through-hole welding positioner has unique middle through-hole design and hand-operated overturning positioner, which is suitable for overlaying welding of inner and outer surfaces of various super long shaft parts. It is equipped with ... -

DNC2000 Planar plasma surfacing system

This set of PTA welding automatic system composed of three parts, included plasma power supply, control console and tooling, mainly for the PTA welding the work piece in shape of flat, such as blade, harvest bade, hammer mill blade, brake valve, gate valve, valve plate and so on.

-

DJC-LC305 Automatic pick plasma cladding equipment

The mechanical walking mechanism adopts imported linear guide rail, driven by stepper motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

DLM-LC501 Double column gantry welding system

The whole machine is driven by imported linear guide rail, precision worm gear reducer and stepping motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

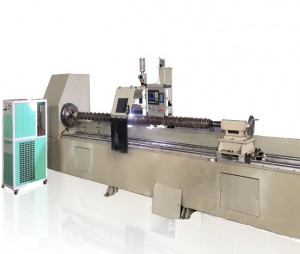

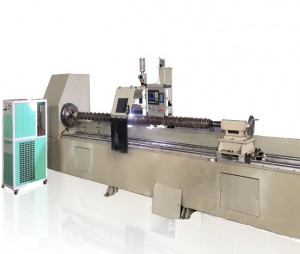

DLG-NC401 Automatic screw welding machine

Plasma powder surfacing is an advanced surfacing technology, which uses argon plasma arc as heat source and powder alloy as filler.Compared with the traditional surfacing methods such as electric welding and argon arc welding, plasma powder surfacing has the characteristics of good surfacing forming, controllable penetration, high adhesion, good density and easy automation. Therefore, it is also the necessary equipment required by the relevant certification departments when valve enterprises apply for special equipment manufacturing license (TS) A-level certification.

-

-

DYY-LC501 Hydraulic rod automatic plasma cladding machine

The machine is driven by imported linear guide, precision worm gear reducer and stepping motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.