Products

-

multifunctional plasma powder welding machine (dml-v02bd)

The plasma power supply DML-V02BD it is for PTA welding some work pieces. The max current 200 A to be flexible to turn between 2-200A as your wish, nimble body would be portable that it is facile to take it to the customer’s spot. Multipurpose, except for the PTA welding, they are applicable for Ion welding, precision argon welding and so on.

-

DH3-HV1700-B06 manipulator positioner

Picture Equipment features HV1700 welding manipulator adopts imported linear guide rail, precision worm gear reducer and stepping motor to drive, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration. Hbt-3 through-hole welding positioner has unique middle through-hole design and hand-operated overturning positioner, which is suitable for overlaying welding of inner and outer surfaces of various super long shaft parts. It is equipped with ... -

DNC2000 Planar plasma surfacing system

This set of PTA welding automatic system composed of three parts, included plasma power supply, control console and tooling, mainly for the PTA welding the work piece in shape of flat, such as blade, harvest bade, hammer mill blade, brake valve, gate valve, valve plate and so on.

-

DJC-LC305 Automatic pick plasma cladding equipment

The mechanical walking mechanism adopts imported linear guide rail, driven by stepper motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

DLM-LC501 Double column gantry welding system

The whole machine is driven by imported linear guide rail, precision worm gear reducer and stepping motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

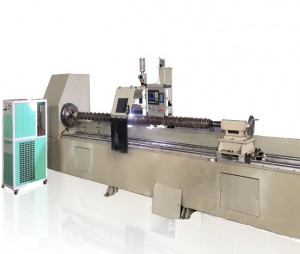

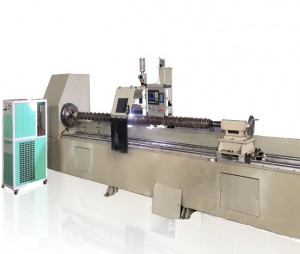

DLG-NC401 Automatic screw welding machine

Plasma powder surfacing is an advanced surfacing technology, which uses argon plasma arc as heat source and powder alloy as filler.Compared with the traditional surfacing methods such as electric welding and argon arc welding, plasma powder surfacing has the characteristics of good surfacing forming, controllable penetration, high adhesion, good density and easy automation. Therefore, it is also the necessary equipment required by the relevant certification departments when valve enterprises apply for special equipment manufacturing license (TS) A-level certification.

-

-

TIG welder for Aluminium——DFC-WSME550

TWS three-frequency composite current control technology Ultra-strong arc resistance Deep dissolution effect is obvious KHZ high-frequency welding High-frequency oscillation arc welding High-quality welding A variety of control modes, to achieve a variety of welding characteristics of the arc output to meet different welding requirements μs-level response to ensure the accuracy and stability of the arc high-speed conversion output Highly integrated inverter chopper module Autoweld communication settings: analog communication: can be configured with analog / discrete analog input and output function of the welding robot or welding machine.485 digital communication: stronger digital transmission capability and longer transmission distance.

-

Robotic Laser cladding System for blades

Laser cladding technology is the use of high-energy laser beam (104-106w/cm2) irradiation of the metal surface, simultaneous melting, expansion and solidification, the substrate surface plated with a layer of materials with special physical, chemical or mechanical properties, so as to form a new layer of alloy with a very low dilution rate, to compensate for the performance of the original substrate material, according to the requirements of the performance of the product, to obtain the heat-resistant, abrasion-resistant, resistance to electricity, corrosion, fatigue or optical, electrical and magnetic properties of the surface layer.

-

All-digital Intelligent Precision Replacement Welding Equipment HRWS-3160

Small heat affected zone. No need for preheating treatment, no annealing of the workpiece after welding. No deformation and collapsed edge. No porosity and sand holes. Accurate and precise welding of small and precise geometrical zones with the finest wires up to 0.1-0.2 mm, easy to use and flexible, direct on-site repair, eliminating the need for costly separation of the workpiece or repair part. It can be used to repair cracks, chips, corners, sand holes and after wear and tear.

-

DYY-LC501 Hydraulic rod automatic plasma cladding machine

The machine is driven by imported linear guide, precision worm gear reducer and stepping motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

precision micro plasma arc welding machine

Plasma arc welding is a welding method using plasma arc as heat source.The gas is dissociated by arc heating and compressed when it passes through the water cooling nozzle at high speed, which increases the energy density and dissociation degree and forms a plasma arc.Its stability, calorific value and temperature are higher than those of ordinary arc, so it has higher penetration force and welding speed.Argon is generally used for the gas forming the plasma arc and the protective gas around it.According to the material properties of various workpieces, argon, hydrogen and other mixed gases are also used.