Products

-

3kw handheld/portable laser cladding machine

3 kW handheld laser cladding equipment is a highly flexible and portable solution. It eliminates the need to disassemble large or fixed workpieces and transport them to a dedicated machining workshop. Instead, repairs or processing can be carried out directly on-site—such as in factory workshops, mines, oilfields, or ships—significantly reducing downtime and logistics costs.

The system features a modular design that makes it easy to transport and install quickly, allowing it to adapt to complex or remote environments (such as offshore platforms or field operations). It is suitable for workpieces of various sizes and shapes, and is particularly ideal for heavy equipment that cannot be moved or would be costly to move—such as rolling mill rolls, turbine blades, and large molds.

-

Automated laser cladding machine

Fully-automatic laser cladding equipment is a high-precision and high-efficiency surface treatment equipment that melts metal powder by laser and deposits it on the surface of the substrate to form a cladding layer that improves abrasion and corrosion resistance.This kind of equipment is widely used in aerospace, automobile manufacturing, mold repair, petrochemical and other industries.

-

Ball Valve Automated Welding Equipment DQF-LC602

Automatic welding equipment designed for cladding spherical valves. The unique spherical valve cladding control system controls the operation of six axes through the system to achieve one-button automatic spherical valve cladding.

-

Cutting picks automatic laser cladding equipment DJC-LC305

The cutting picks welding equipment is a model custom-designed for surface cladding of mining cutting picks. The equipment has a small footprint, an integrated enclosed design, and an attractive appearance. It is equipped with a visual welding observation window, a simple PLC control system, and one-button automatic cladding start-up, which lowers the threshold for operators to use. It can provide customized services for single and double workstations.

-

Laser cladding machine for blades

This is a high-end automated laser cladding machine designed for blades repair and remanufacturing.

The laser welding machine employs a mainstream international “six-axis industrial robot” as its core motion platform, integrated with a high-energy-density “fiber laser” and an “automatic powder feeding system” to achieve multi-angle, multi-directional spatial cladding processing.

The laser welding machine offers high flexibility, precision, and consistency, making it particularly suitable for repairing and reinforcing complex curved components such as aircraft engine blades, flat blades, and precision cutting tools.

-

DNC2000 Planar plasma surfacing system

This set of PTA welding automatic system composed of three parts, included plasma power supply, control console and tooling, mainly for the PTA welding the work piece in shape of flat, such as blade, harvest bade, hammer mill blade, brake valve, gate valve, valve plate and so on.

-

DJC-LC305 Automatic cutting picks plasma cladding equipment

The mechanical walking mechanism adopts imported linear guide rail, driven by stepper motor, with small transmission clearance, high rigidity, stable and reliable operation and convenient integration.

-

high integration, integrated plasma powder welding machine (dml-v03bd)

Dml-v03bd is a highly integrated high-power plasma powder welding machine, which integrates plasma arc power supply, host power supply, high-power refrigeration water tank and powder feeding controller, with programmed linkage control.It is convenient and flexible to use.

-

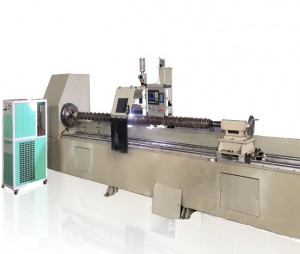

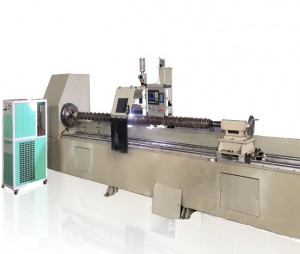

Screw Automatic Welding Equipment DLG-LC501

This equipment is specifically designed for screw and shaft cladding welding requirements. The machine tool adopts a fully automated PLC control system, integrated with high-precision servo drives and an intelligent welding process library, offering a wide range of applications (including outer circular parts, screws, spiral blades, etc.). It is equipped with adaptive arc voltage tracking technology, ensuring high stability, and supports seamless switching between arc welding, MIG, and TIG welding processes with a single button. The compact horizontal structure design, combined with a modularized column system, enables quick adjustments to product processes. The equipment offers customized services, with different specifications available based on the size of the equipment.

-

DLG-NC401 Automatic screw welding machine

Plasma powder surfacing is an advanced surfacing technology, which uses argon plasma arc as heat source and powder alloy as filler.Compared with the traditional surfacing methods such as electric welding and argon arc welding, plasma powder surfacing has the characteristics of good surfacing forming, controllable penetration, high adhesion, good density and easy automation. Therefore, it is also the necessary equipment required by the relevant certification departments when valve enterprises apply for special equipment manufacturing license (TS) A-level certification.

-

DM-PT4000 Plasma arc welding machine

PT4000 is a high-power plasma welding machine, equipped with high-power refrigeration water tank, high stability, high temperature environment can work for a long time, suitable for thick plate welding.

-

120A Deep Hole Welding Torch

120A Deep Hole Welding Torch is a high-efficiency welding tool designed for narrow space and deep hole parts, with high current output, good heat dissipation, compact structure, easy maintenance, etc. It is widely used in mold repair, pressure vessel, aerospace, and other precision welding fields, supporting customized lengths and cooling modes, and adapting to a wide range of welding equipment.