precision micro plasma arc welding machine

Features

1、Foil and sheet can be welded by micro plasma arc welding;The arc energy is high, the welding heat affected zone is small, and the welding deformation is very small;

2、The arc column has large rigidity, small hole effect, fast welding speed and high production efficiency, which is 3-6 times of that of ordinary argon welding;

3、There are few weld defects, many weldable materials and high welding quality;

4、Excellent repetitive production, electrode shrink in the nozzle, not easy to pollution and burn;

5、The plasma arc has high energy density, high arc column temperature and strong penetration ability;

6、The arc column is slender and has strong penetration. The thin-walled workpiece can be directly welded through and the preparation time can be shortened. The steel with the thickness of 0.3 ~ 1 mm can be welded through and formed on both sides (i.e. single side welding and double side forming) without groove. The stress deformation is small.

Dml-v01a host parameters

|

Precision micro plasma arc welding machine |

|||

| Main technical parameters and models |

DML-V01A |

||

|

Continuous welding |

Pulse welding |

Precision pulse welding |

|

| Arc current (a) |

2.0-5.0 |

||

| Welding current (a) |

0.1-10-40 |

||

| Base current (a) |

0.1-10-40 |

||

| Rise time (s) |

0.0-5.0 |

||

| Descent time (s) |

0.0-5.0 |

||

| Welding time (MS) |

|

1-500 |

1-500 |

| Interval time (MS) |

|

10-500 |

|

| Air delivery in advance (s) |

1-10 |

||

| Gas time delay (s) |

1-20 |

||

| Ion gas (L / min) |

0.25-2.5 |

||

| Protective gas (L / min) |

1-25 |

||

| Input voltage (V) |

AC220V,50HZ |

||

| Rated input capacity (kVA) |

1.1 |

||

| Load duration rate (%) |

60% |

||

| Weight (kg) |

28 |

||

| External dimension of power supply (mm) |

590*330*300 |

||

Advantages

1、The thickness of the welding strip is smaller than that of argon arc welding, usually 0.3-0.5mm. It can be welded without curling, and the welding quality is good.

2、In the continuous automatic welding of pipes, the change of plasma arc length has little effect on the welding quality, which is different from that of argon arc welding.

3、When the welding current is very small (less than 3a), the stability of micro plasma arc is good, while the stability of argon arc is poor.

4、Due to the heat concentration, the welding speed of micro plasma arc is higher than that of argon arc welding, and the productivity is high.

5、Can weld a variety of metals, including stainless steel, non-ferrous metals and refractory metals.

Application fields

1、Electronic and electrical components (thermocouple, motor, silicon steel sheet, etc.)

2、Instruments, medical equipment (metal bellows, precision instrument components, etc.)

3、Welding of special metals (such as titanium, nickel, molybdenum and other special metals can also implement efficient welding)

4、Aircraft and aerospace (aircraft accessories, space station accessories, relays, gas sensors, etc.)

The continuous automatic micro plasma arc welding of ultra-thin wall pipe is similar to the process of closed compression arc welding.The insulation sleeve is installed between the welding die sleeve and the welding torch to ensure the reliable insulation between the plasma welding torch and the metal parts. At the same time, the protective argon is sealed in a small chamber. The process parameters of micro plasma arc welding for ultra-thin wall pipe are more than those of argon arc welding. In addition to the welding current, welding speed and protective gas flow, there are also the flow rate of working gas, the composition of protective gasThese parameters affect the welding quality.Experience shows that the main process parameters affecting the productivity of ultra-thin wall pipe are welding current, working gas flow rate and nozzle hole diameter.

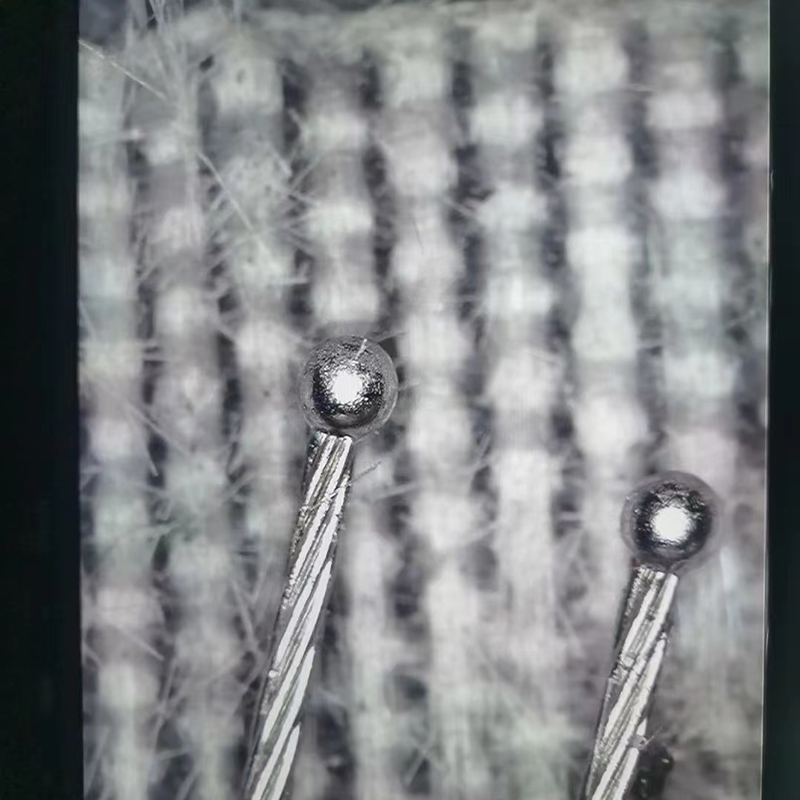

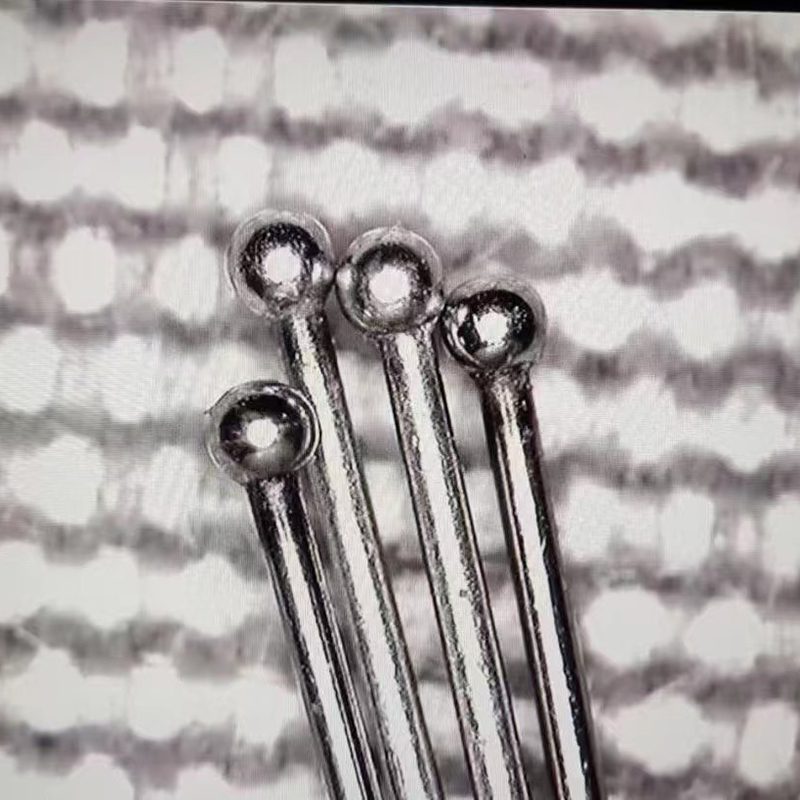

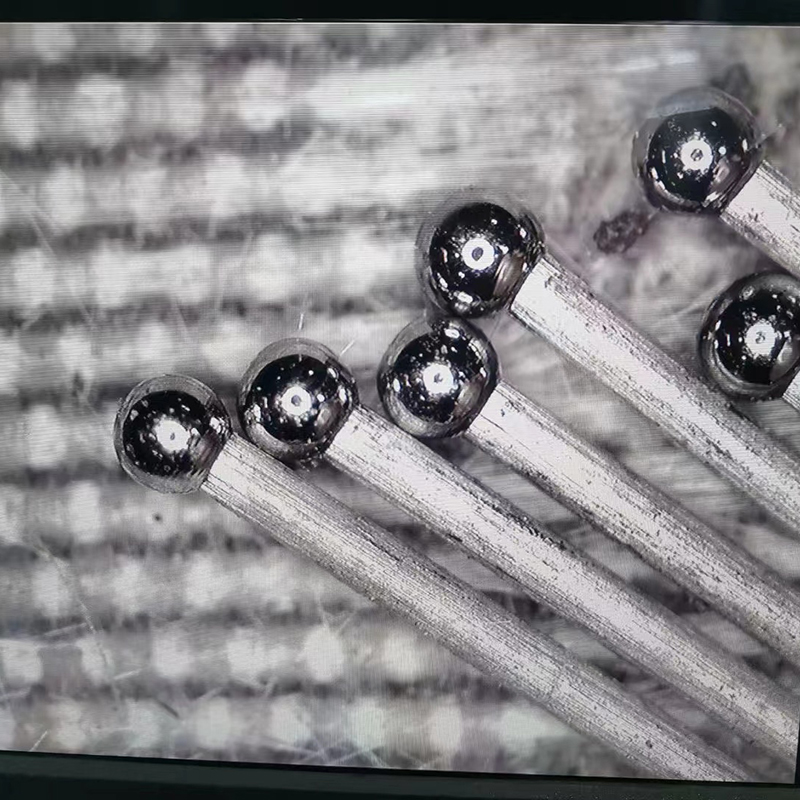

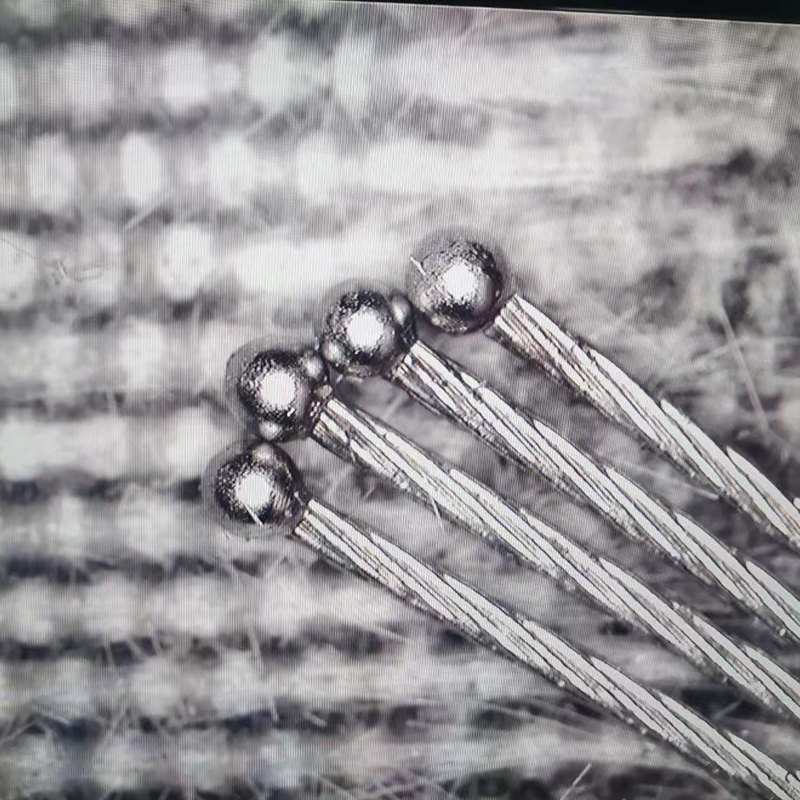

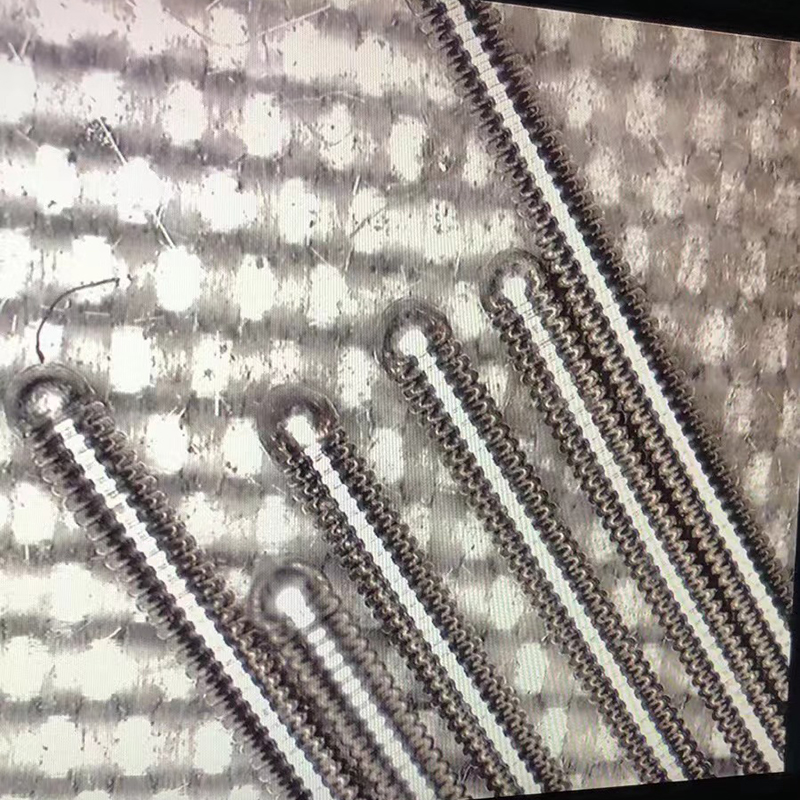

Picture display