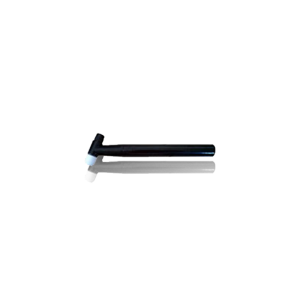

Plasma torch 80A

Basic Introduction

This plasma torch is for plasma butt welding with smart shape, consisted of thermal elements and nozzle and the water cooling system located inside.

It is safe to deal with by both hand and automatic. Due to the small and deft, it is carefree to enter the place where other tool hard to go. Because the low power, it is fair to welding dainty work pieces.

During the working, the angle of plasma and torch between 80-110 is recommended. If the angle is overlarge, the splash would be as well. When the angle of plasma torch and work piece is the caster angle. (The arc always is toward to welded parts)the welding bread is narrow, melting pool is deep and the formation is not good. When it is the front rake, it would get a wide welding beam, melting pool is shallow and good formation.

And it is safe to apply. when it is welding by hand and here is a holder for it. And avoid to contact the nozzle as it is working

Sometimes, the nozzle would be blocked by powder, it is essential to clean termly.

When the welder stop working, it is required to rest 10 minutes to put away after cutting power.

Product Parameters

| Mode | PT8013-HQ |

| Main Arc | Water-electricity integration |

| Tungsten electrode-Workpiece | Negative-Positive |

| Mode of Tugsten | 2.4 |

| Arc Voltage | 90V |

| Welding Current | 3-80A 90% temporary load rate |

| Pilot Arc | Water-electricity integration |

| Tungsten-Nozzle | Negative-Positive |

| Pilot Arc Current | 3-20A 100% Temporary load rate |

| Mode Powder feeding | Aggregate |

| Volume Powder feeding | Max. 50g/Min |

| Gas Powder feeding | 1.0-3.0L/min |

| Type Powder | Alloy Powder |

| Size Powder | 70-200um |

| Passage Powder feeding | Single gas passage |

| Cooling | Main arc cooling |

| Ion gas | 0.5-2L/min |

| Shield gas | 5-25L/min |

| Nozzle Cooling | Water cooling indirectly |

| Diameter Nozzle | 0.8-2.5 mm |

| Length Cable | 4 m (customized avaiable) |