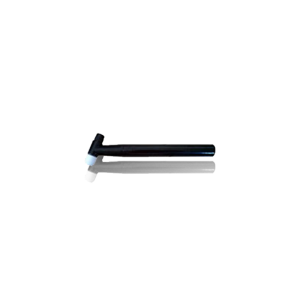

Plasma torch 500A

Equipment Features

The 500A plasma surfacing torch consists of three parts: upper part, lower part and insulator.The upper part is used to fix the tungsten pole and to connect the water and electric joints. The lower part is to install nozzle and being a part of a water-cooled cavity of the one, connecting the pipelines joints of water, electricity, gas and powder; Insulators ensure ones between the upper and lower as well as connects them. The protection gas completes diffuses inside the torch to form uniform protection. Powder feeding pipeline is inlaid by itself inside the torch to make the powder feeding system unblocked.

Installation Notes

To make sure performance well, please use and maintain correctly.It must be carried out under the state of machine shutdown when replacing of nozzle, sealing ring and central ring and keep the place of torch is higher than water tank's to avoid cooling water flow into the powder feeding channel.When the tungsten pole is disassembled, the pilot arc must be off. Check the sealing ring and put it into the sealing groove smoothly after confirming that it is new and free scratches.

Danger

Do not touch live components.

Stand on a dry insulating mat to protect yourself from the ground in dry insulating gloves.

Do not use wet or damaged gloves.

Do not touch hot parts with bare hands

Note

In continuous use of torch, there should be a cooling period before use.

Keep your head away from the smoke.

Use forced ventilation and smoking devices to remove smoke.

Use a fan to remove smoke.

Comply with environmental regulations when removing smoke and dust.

Wear protective clothing, welding caps, and choose appropriate filters.

Product Parameters

| Mode | DPT-50019 |

| Main arc polarity | Tungsten electrode to negative electrodeWork piece to positive electrode |

| Pilot arc polarity | Tungsten electrode to negative electrodeNozzle to positive electrode |

| Tungsten electrode dimension | 6.0mm |

| Arc voltage | 90V |

| Current | 30-500A 80% duty cycle |

| Cooling type | Circulation cooling of main arc and pilot |

| Nozzle cooling | Water cooling |

| Ionic gas | 0.6~6L/min |

| Shielding gas | 5~25L/min |

| Powder feeding gas | 0.6~6.0L/min |

| Powder feeding gas circuit | Two gas paths enter independently |

| Powder feeding volume | 8kg/h Max |

| Powder type | Metal powder |

| Granularity | 70~200um |

| Powder feeding type | By the feeding hole |