plasma powder surfacing machine DML-V03CD

DML-V03CD working principle

Plasma powder surfacing is a kind of surfacing technology which uses plasma arc as heat source, uses high temperature produced by plasma arc to heat alloy powder and substrate surface rapidly and melt, mix, diffuse and solidify together. After plasma beam leaves, it self excites and cools to form a layer of high-performance alloy layer, so as to realize strengthening and hardening of part surface The thickness, width and hardness of the surfacing layer can be adjusted freely within a certain range by adjusting the relevant surfacing parameters. After plasma powder surfacing, a fusion interface is formed between the base material and the surfacing material, which has high bonding strength; the surfacing layer has compact structure, good corrosion resistance and wear resistance; the dilution of the base material and the surfacing material is reduced, and the material characteristics change little; using powder as the surfacing material can improve the selectivity of the alloy design, especially the refractory material can be successfully overlaid, and the wear resistance and wear resistance of the workpiece can be improved High temperature, corrosion resistance.

DML-V03CD Technical advantages

1. The results show that the cladding alloy layer has metallurgical bonding with the workpiece substrate, and the bonding strength is high;

2. The dilution rate of plasma arc surfacing can be controlled within 5% - 10%, or less.

3. It is easy to realize mechanization and automation in surfacing process;

4. It can directly carry out plasma surfacing on the surface of corroded and greasy metal parts without complicated pretreatment process;

5. Compared with other plasma spray welding equipment, it has the advantages of simple structure, energy saving, easy operation and maintenance;

6. The plasma arc has the advantages of high temperature, concentrated energy, good stability and small residual stress and deformation on the workpiece.

7. Good controllability. The parameters of plasma arc such as atmosphere and temperature can be adjusted by changing the power, the type of gas, the flow rate and the structure size of the nozzle, so as to realize efficient automatic production and improve labor productivity.

8. A wide range of materials are used. As a deposit material, hardfacing alloy powder is not limited by casting, rolling, wire drawing and other processing technology. According to different performance requirements, different composition of alloy powder can be configured. It is especially suitable for hard wear-resistant alloy which is difficult to wire but easy to powder, so as to obtain the required performance of hardfacing layer.

DML-V03CD Host parameters

| Name |

plasma powder welding machine |

|||

| Model |

DML-V03CD |

|||

| Category | Assembly | Structural parameters | Data | |

|

Welding machine power supply |

Highly integrated all in one machine

|

Rated voltage(V) | AC380 50HZ | |

| Rated input power(KW) | 25KW | |||

| Function selection |

Continuous welding |

Pulse welding |

||

| Arc current (A) |

3-20 |

3-20 |

||

| Welding current (A) |

3-500 |

3-500 |

||

| Base current (A) |

3-500 |

3-500 |

||

| Current rise time (s) |

0-5.0 |

0-5.0 |

||

| Current drop time (s) |

0-5.0 |

0-5.0 |

||

| Pulse welding time (MS) |

|

1-999 |

||

| Welding interval (MS) |

|

10-990 |

||

| Advance feeding time (s) | 0-5 | |||

| Lagging powder feeding time (s) | 0-5 | |||

| Gas protection time (s) | 1-20 | |||

| Load duration rate (%) | 90 | |||

| Weight (kg) | 161 | |||

| Dimensions(mm) | 800*500*1558 | |||

|

Cooling system |

Air conditioning refrigeration | Power (W) | 2000 | R22 refrigeran |

| Compressor power (HP) | 1/2 | Panasonic | ||

| Rated exhaust air volume (m³/h) | 600 | |||

| Rated heat discharge(W) | 2200 | |||

| Rated power of fan(W) | 36 | EBM in Germany | ||

| Internal water storage (L) | 8.5 | 304 stainless stee | ||

| Pump power(W) | 90 | South special pump | ||

| Rated head(M) | 21 | |||

| Rated flow(m³/h) | 1.1 | |||

| Front Noise(dba) | 52 | Baking paint for thickened steel plate | ||

| welding torch | Integrated die casting | Powder spraying form | Double hole taper symmetrical powder feeding | |

| Applicable current(A) | 5-300 | |||

| Suitable for powder(mesh) | 100-270 | |||

| Sustainable working time(h) | >20 | |||

| Length of torch holder and torch wire(M) | 8 | |||

| Water cooling mode | Water cooling of welding torch nozzle | |||

| Powder feeder | Powder feeding form | Accurate powder feeding by impeller | ||

| Control mode | Motor direct drive | |||

| Storage capacity(KG) | 8 | |||

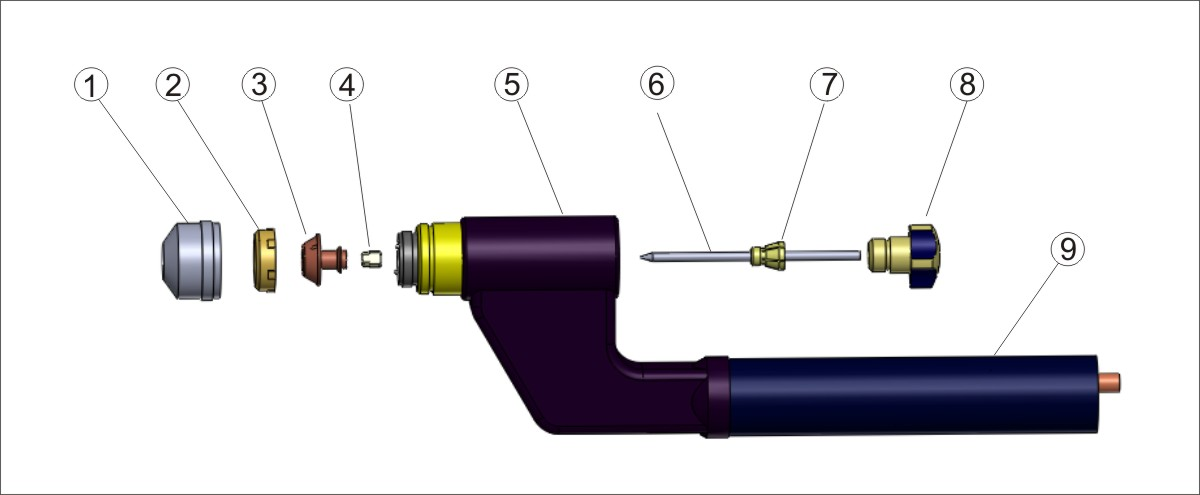

Structure drawing of plasma welding torch

(schematic diagram of 300A stack welding gun)

1 gas shield 2 copper nozzle locking ring 3 copper nozzle 4 middle ring 5 surfacing gun body 6 tungsten electrode 7 tungsten electrode clamp 8 welding gun cap

Configuration list

| Name | Specification configuration | Model | Quantity | Remarks | |

| Plasma stack welding machine | DML-V03CD | 1 | |||

| Plasma welding torch | 1 | ||||

| Powder feeder | 1 | (accurate impeller type powder feeding) | |||

| Argon pressure reducer | 0-25 | yqAr-731L | 2 | Floating ball | |

| Foot control switch | 1 | ||||

| Cooling water tank | 1 | (2P refrigeration) | |||

| Tool box | 1 | Including common accessories | |||

| Instructions | 1 | ||||

| Warranty card | 1 | ||||

| Dimming cap | 1 | ||||

| Ground wire | 1 | ||||

| Gas hose | M | According to the actual needs of users | |||

The difference between plasma welding machine of DuoMu and plasma welding machine on the market

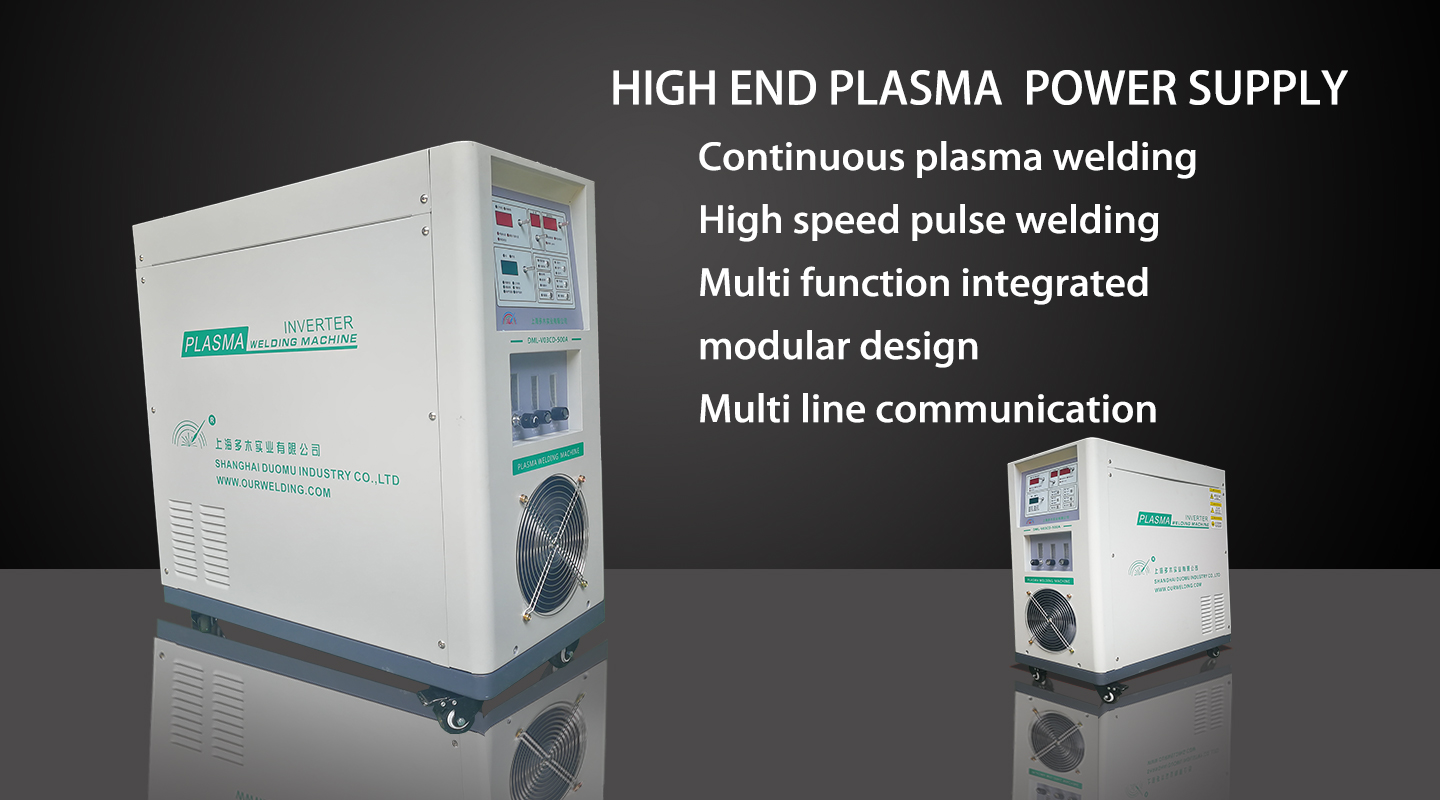

Welding machine power supply:At present, most of the plasma powder stack welding machines in the market are high-power, which is due to the problem of plasma power supply to a certain extent. At present, the structure of high-power plasma stack welding machines is mainly composed of two large and small power argon arc welding machines, with small power argon arc welding guiding the main arc and high-power argon arc welding guiding the main arc. Plasma stack welding machine of DuoMu is to overcome the above problems, using pure plasma power supply system, small size, light weight, suitable for any occasion.

Plasma torch:At present, most of the plasma stack welding guns in the market are external powder feeding system, and the handle of the welding gun is also made of common materials, which is easy to cause powder blockage or electric leakage in the process of use, seriously affecting the normal production needs and the life safety of users. The Plasma stack welding gun of DuoMu adopts the built-in powder feeding system, and the handle of the welding gun is made of polyethylene insulation material, which overcomes various problems. The carrying current of the welding gun is not enough to meet the full load of the machine.

Powder feeder:At present, the scraper type powder feeding is used in the plasma stack welding machine in the market. This kind of powder feeding method is easy to cause uneven powder feeding and powder blocking, which will affect the normal production needs. The plasma stack welding machine of DuoMu adopts the most advanced impeller type powder feeding, which can accurately control the size and speed of powder feeding, thus overcoming the above problems.

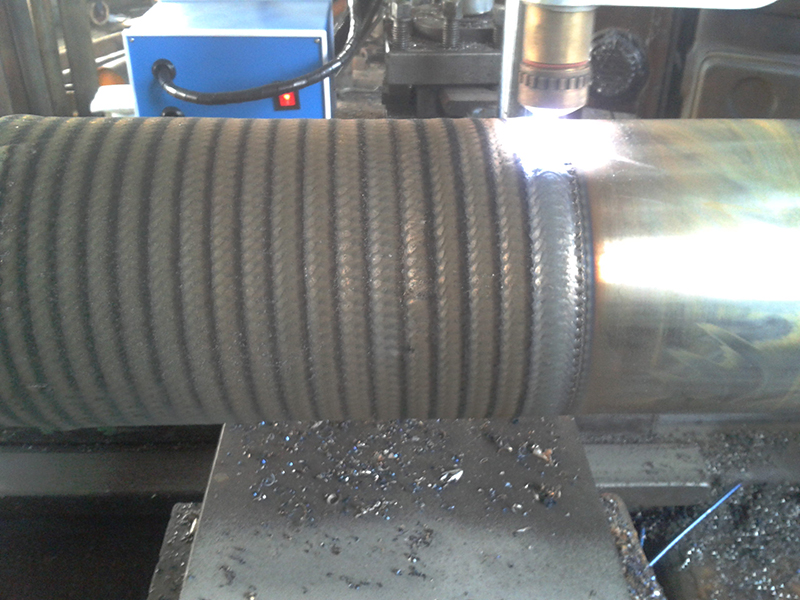

Cases

Welding machine power supply:At present, most of the plasma powder stack welding machines in the market are high-power, which is due to the problem of plasma power supply to a certain extent. At present, the structure of high-power plasma stack welding machines is mainly composed of two large and small power argon arc welding machines, with small power argon arc welding guiding the main arc and high-power argon arc welding guiding the main arc. Plasma stack welding machine of DuoMu is to overcome the above problems, using pure plasma power supply system, small size, light weight, suitable for any occasion.

Plasma torch:At present, most of the plasma stack welding guns in the market are external powder feeding system, and the handle of the welding gun is also made of common materials, which is easy to cause powder blockage or electric leakage in the process of use, seriously affecting the normal production needs and the life safety of users. The Plasma stack welding gun of DuoMu adopts the built-in powder feeding system, and the handle of the welding gun is made of polyethylene insulation material, which overcomes various problems. The carrying current of the welding gun is not enough to meet the full load of the machine.

Powder feeder:At present, the scraper type powder feeding is used in the plasma stack welding machine in the market. This kind of powder feeding method is easy to cause uneven powder feeding and powder blocking, which will affect the normal production needs. The plasma stack welding machine of DuoMu adopts the most advanced impeller type powder feeding, which can accurately control the size and speed of powder feeding, thus overcoming the above problems.

Surface

Round roll