Blades are the core components of various cutting tools, which are widely used in industrial manufacturing, machining, daily life and many other fields. Their main role is to process and handle materials by cutting, dividing and engraving.

Why blade cladding?

Conventional inserts are prone to wear and damage during high-load, high-speed cutting operations, resulting in frequent replacements and high maintenance costs.

Application areas of blades

Blades have a wide range of applications in many fields:

• Industrial Manufacturing and Processing

• Medical

• Daily Life

• Beauty and Personal Care

• Other Specialized Fields

• Safety & Rescue

What is blade cladding technology?

Blade cladding is an advanced process that significantly improves the performance of blades by depositing a coating of high hardness and wear-resistant material on the blade surface. Coating technology often uses heat sources such as lasers, plasma, or flames to rapidly melt and spray the coating material onto the blade surface to form a dense, uniform coating. Coating technology provides higher adhesion and better performance than traditional surface treatment methods.

History of the technology

The development of blade surface cladding technology has gone through several stages:

• Initial exploration stage: In the 1970s, scientists began to try to apply cladding technology on the surface of cutting tools. The early cladding process mainly focused on flame spraying and plasma spraying, but due to technical limitations, the coating quality and adhesion is low, the actual application effect is not ideal.

• Technological breakthrough stage: into the 21st century, the development of laser cladding technology for blade surface cladding has brought a new breakthrough. Laser cladding has the advantages of low heat input, dense coating, strong controllability, etc., which makes the performance of the cladding coatings significantly improved, and began to gradually promote the application in the high-end manufacturing industry.

• Widely used stage: In recent years, with the continuous progress of materials science and surface engineering technology, the cost of cladding technology has been gradually reduced, and the scope of application has become more and more extensive. Blade cladding technology has been successfully applied to a wide range of tools such as turning tools, milling cutters, drills, etc., and has shown great potential in the fields of aerospace, automobile manufacturing and precision machinery.

Choosing the right type of cladding machine

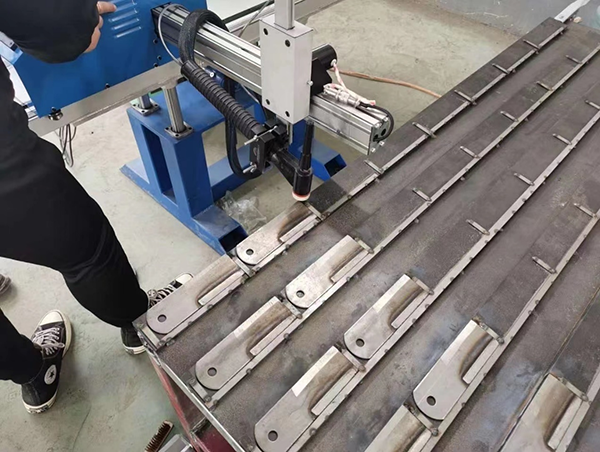

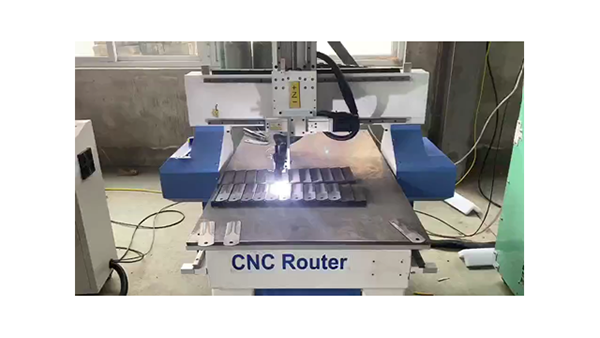

DNC2000 Plane Plasma Surfacing System

This set of PTA welding automatic system composed of three parts, included plasma power supply, control console and tooling, mainly for the PTA welding the work piece in shape of flat, such as blade, harvest bade, hammer mill blade, brake valve, gate valve, valve plate and so on.

Advantages of the technology

Blade cladding technology offers a number of significant advantages over conventional tools:

• Significantly improved wear resistance: the high hardness and wear resistance of the fusion-coating coating significantly extends the service life of the insert, reducing the need for frequent replacement and maintenance.

• Enhanced cutting performance: Fusion coating technology makes the insert surface smoother, reducing cutting friction and heat generation, improving cutting efficiency and workpiece surface quality.

• Enhance corrosion resistance: Fusion coating can effectively resist the erosion of acids and alkalis and other corrosive substances, extending the service life of the tool in harsh environments.

• Green environmental protection: the fusion coating process uses environmentally friendly materials, reducing the emission of harmful substances, in line with the trend of green development of modern industry.

Challenges and future prospects

Despite the many advantages of blade cladding technology, there are still some challenges to be faced in practical applications:

1.Cladding uniformity: Ensuring that the coating is uniformly distributed on the insert surface to avoid localized performance inconsistencies.

2.Material Selection: The selection of the right coating material for different cutting environments in order to achieve the best performance.

3.Process optimization: Continuously optimize the coating process parameters to improve coating quality and productivity.

There are many types of blades, each of which plays an important role in different fields according to its use and characteristics. From industrial manufacturing to everyday life, from medical surgery to high-tech fields, blades are used everywhere. Their performance and quality directly affect the processing efficiency and product quality. Through this background introduction, we hope that readers can have a more comprehensive understanding of the development of blade cladding technology, its technical advantages and future application prospects!

Post time: Aug-08-2024