Plasma Transfer Arc Welding(PTA) and Plasma Arc Welding(PAW) are both plasma-based welding technologies, but they are significantly different in terms of process principles, functions and application scenarios.

Principle differences

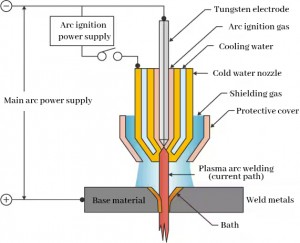

Plasma Arc Welding(PAW)

Plasma arc welding is based on the principle that a high energy density plasma arc is formed by dissociating gases through arc heating and compressing them through a water-cooled nozzle. The arc is generated between a tungsten electrode and the workpiece, and the connection is achieved by melting the edges of the workpiece by means of the high-temperature plasma arc. The weld is formed primarily by melting of the base metal, usually without the addition of filler material. It is mainly used for welding.

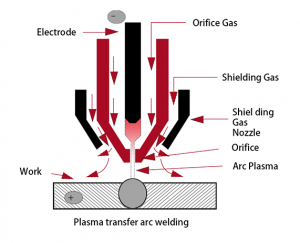

Plasma Transfer Arc Welding(PTA)

Plasma transfer arc welding is based on the action of a high-temperature heat source from a plasma arc, which melts the plasma cladding material (metal or alloy powder) and forms a metallurgically bonded, reinforced coating to the surface of the substrate. The arc is generated between a tungsten electrode and a molten pool, with the transfer arc providing additional energy to melt both the base material and the powder. The fusion cladding is formed by the filler material (powder) and the base material is heated only to a moderately molten state to ensure a good bond. It is mainly used for fusion cladding.

Features and Applications

Plasma Arc Welding (PAW)

Plasma arc welding is characterized by low heat input and high welding precision. It is suitable for welding of precision parts and thin plates. Common application areas are:

• Aerospace

• Electronics

• Automotive and other fields that require high welding quality.

Plasma Transfer Arc Welding (PTA/PTAW)

Plasma Transfer Arc Welding (PTA/PTAW) is mainly used for surface strengthening, improving the wear resistance, corrosion resistance and high temperature performance of the base material through plasma cladding. The cladding layer is firmly bonded to the base material, the cladding material is controllable, and the heat area has little influence. It is usually used for the repair and strengthening of valves, pump housings and wear parts. Common application areas are:

• Petrochemicals

• Energy

• Mining, etc.

Comparison of PAW and PTA/PTAW

| Welding Type | Plasma Arc Welding (PAW) | Plasma Transfer Arc Welding (PTA/PTAW) |

| Purpose | Welding Workpiece Connection | Enhancement of surface properties by cladding |

| Heat Source | Plasma Arc | Transfer arc and plasma arc |

| Filler material | Usually none (sometimes wire) | Alloy powder |

| Applications | High precision welding | Surface repair and strengthening (wear layer) |

| Characteristics | Smaller heat affected zone, high precision | Customizable cladding materials, versatile coatings |

In general PAW is suitable for precision welding, while PTA/PTAW is more focused on surface strengthening. Both complement each other in application scenarios. Choose the welding technique that suits your needs, and in special cases you can also combine different welding techniques to improve welding efficiency.

Post time: Jan-20-2025