For more than15 years, welding turntables have been one of the strengths of Duomu.

Being a business with an ISO 9001 certification, Duomu will never fail you!

You can place your full trust in us for all your welding turntable needs!

Duomu’s Welding Turntable Options

Duomu’s welding turntables can help secure a workpiece both in place and in motion. We offer high quality welding rotary turntables to rotate your workpieces in automation.

Duomu is popular in the industry for providing reliable and dependable welding turntables.

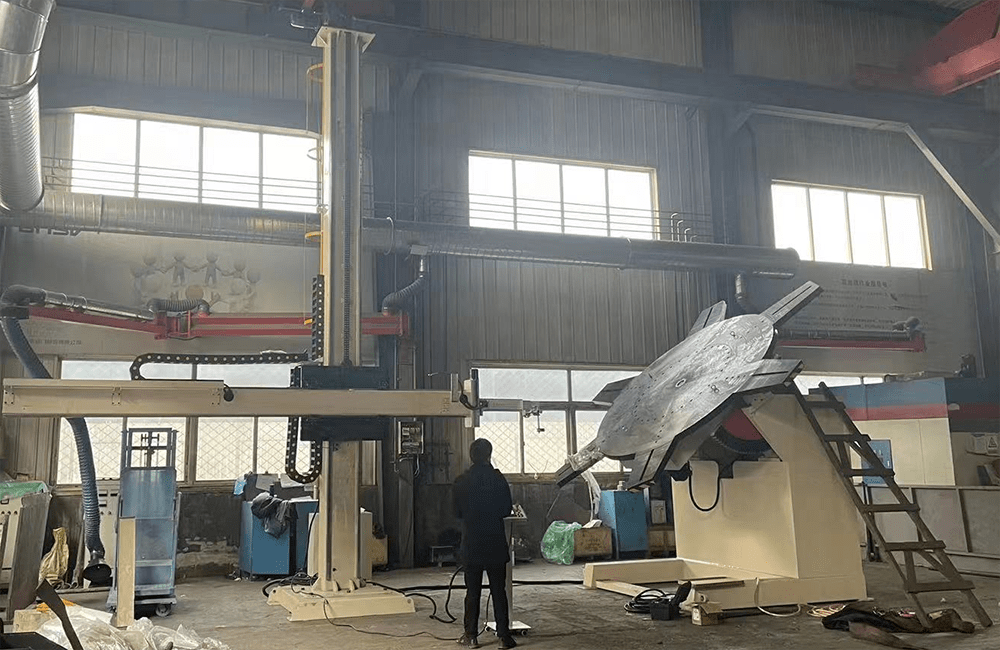

Welding turntable ↑

From regular welding positioners for small and light work pieces, to heavy and industrial welding turntables for welding and maneuvering heavy parts, Duomu will be the best option for you!

Duomu can produce the specific welding turntable positioner depending on what you need.

In fact, we can get you whatever welding turntable you need; should you need a regular flat-surfaced turntable, even a turntable with a 3-jaw chuck surface!

Why Duomu Welding Turntables ?

Many companies rely on Duomu for their welding turntables. This is because we offer the following advantages:

Fast delivery of products (within 20 days)

All parts of the positioner are perfectly constructed

Electrical control components from the best manufacturers

Complete installation service without skipping any steps

High quality after-sales service

As an organisation, we are certified in all matters related to welding and welding equipment.

Welding positioner ↑

Huge welding turntable 15T Load ↑

HBT-003 through-hole welding displacement converter

Equipment features:

The overall sheet metal structural frame, thick sheet metal, solid steel profile material, the overall frame welding, with a strong bearing seat, the bearing capacity is large, and the durable skin is solid.

The unique through hole design of the open hole welding converter is adapted to the internal and external round surface pile welding operation of various ultra-long shaft parts. It is equipped with stepping motor drive to achieve the precise drive of the main shaft, small clearance, high rotation accuracy and convenient control.In addition, use welding tray with high accuracy and good concentricity.

The handpiece flip uses hand wheel and precision worm worm with self-locking function to accurately adjust the flip speed.Flip Angle 0- -120;

Welding turntable through-hole HBT-003 ↑

Specification:↓

| Configure the project | Main parameter description | Configure the project | Main parameter description | Configure the project | Main parameter description |

| Total quality of equipment | About 45KG | rated load | 30 KG | electric rotating machinery | stepper motor |

| Turn the center high | 200 mm | The center of gravity distance | 50 mm | Flip way | Hand shake wheel manual |

| Medium hole diameter | not have | eccentricity | 50 mm | Rotate the reducer | Turboworm speed reducer |

| Working disk diameter | 250 mm | spin velocity | 0.01~20 r/min | navar | PLC |

| Maximum rotary diameter | 400 mm | Flip speed | —— | Maximum flip angle | 120° |

| Reference occupation, ground size | Approximately 470 mm long and 385 mm wide High height 395 mm. | ||||

There are so many types to choose from and all are customized for each client. Any parameters as you need!

Shanghai Duomu, your trustworthy supplier and reliable friend from China!

Post time: Dec-04-2023