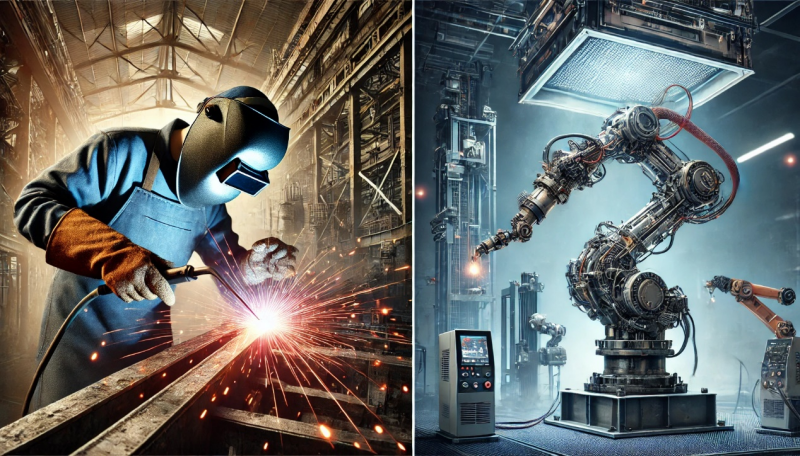

The welding industry has been undergoing a technological revolution in recent years, and the gradual replacement of manual welders by automated welding equipment and robots has sparked widespread controversy in the industry. On the one hand, proponents argue that welding automation improves productivity, reduces labor costs, and reduces health damage to workers from intense welding work; on the other hand, critics worry that a large number of experienced welders are out of work, and the industry is losing skilled personnel.

Welding robots are on the rise, and companies are rushing to them

According to the latest industry data, the global welding robot market has grown by nearly 40% in the past five years, especially in automotive manufacturing, shipbuilding, bridge construction and other areas, the penetration of automated welding equipment has increased dramatically. Numerous companies have invested heavily in upgrading their production lines to reduce labor dependency and improve welding precision.

“Traditional welding requires highly skilled workers, while automated equipment can realize 24-hour uninterrupted operation and reduce human error.” The head of a large manufacturing company said, “In the long run, this is an inevitable trend.”

Welders survival crisis? The industry is facing polarization

However, not all welders are optimistic about this trend. In recent years, many senior welders have been forced to change careers, and even a “welding talent gap” problem. According to a survey by the Welding Industry Association, more than 60% of welders believe that the rise of automated welding has affected their job prospects.

“Robots can handle simple welding on the assembly line, but complex welding, restorative welding, etc. still need manual operation.” One welder said, “If young people don't want to learn to weld, we may face a shortage of skilled tradesmen.”

Technological progress vs. labor value: where does the welding industry go from here in the future?

Experts pointed out that the popularity of automated welding does not mean the complete disappearance of welders, but the performance of the industry's technological upgrading. In the future, the welding industry may be “intelligent + artificial refinement” direction, that is, let the robot to undertake repetitive work, while the artificial welder is focused on fine, difficult welding tasks.

At the same time, the government and vocational education institutions are also strengthening the skills training of welding personnel, promoting the traditional welders to intelligent equipment operators, welding engineers and other new positions to adapt to the industry change.

Conclusion: the welding industry in the midst of change

The rapid development of welding automation will undoubtedly continue to change the entire industry ecology. In the future, welders need to continuously improve their skills to adapt to the new market demand. While companies in the pursuit of efficiency, but also should take social responsibility for the welding talent to provide transformation opportunities. Whether it is “machine instead of man”, or “man-machine collaboration”? This controversy about the future of the welding industry will continue to ferment.

Post time: Feb-27-2025