Recently, our company successfully completed the production, transportation, installation and debugging of one set of plasma cladding automation equipment and one set of laser cladding automation equipment, and dispatched a professional technical team to the customer's site in Russia to carry out the comprehensive installation, debugging and operation training of the equipment. Through high-quality equipment and professional technical support, the company won the high praise of the customer, fully demonstrating the excellent strength and service level of our company in the field of industrial automation equipment.

High-precision equipment to help customers upgrade production

The plasma cladding and laser cladding automation machines delivered here are the result of today's state-of-the-art technology and excel in their performance and reliability in the customer's production process.

Equipment overview and technology highlights

Plasma cladding automation equipment: Equipped with advanced numerical control system, the equipment realizes fully automatic cladding operation and supports multi-axis linkage processing of complex workpiece surfaces, which greatly improves production efficiency and processing quality. Equipped with intelligent control system, it can adjust the current, voltage, gas flow and other parameters in real time to ensure uniform coating thickness and strong adhesion. The plasma arc has extremely high temperature and energy density to melt the cladding material quickly, realizing efficient and stable cladding process.

Laser cladding automation equipment: Adopting the international leading laser cladding technology, it can realize high-intensity and high wear-resistant metal surface treatment, which is widely used in the manufacturing industry for strengthening and repairing the key parts. The equipment has stable performance, supports long-time continuous operation, and adapts to complex industrial application scenarios.

The delivery of these equipments not only meets the customer's demand for high-performance industrial equipments, but also provides strong support for its goal of realizing an intelligent factory.

Full-process service to ensure the smooth progress of the project

After the delivery of the equipment, our company dispatched a team of senior engineers and technical experts to the customer's site in Russia to provide a full set of services, including equipment installation, commissioning, and functional verification.

After the successful commissioning of the equipment, the team also provided comprehensive technical training to the customer's staff covering:

• Equipment operation process: standardized process from start-up to shut-down to ensure safe and efficient use.

• Troubleshooting and treatment: explanation and on-site demonstration for possible problems.

• Maintenance tips: including cleaning of core components, replacement cycles and precautions.

• Process Optimization Suggestions: Provide customized process parameter configuration guidance according to customer's specific production needs.

Through the combination of theory and practice, we ensure that the customer's team can quickly master the operation and maintenance skills of the equipment, and provide a guarantee for the long-term stable operation of the equipment.

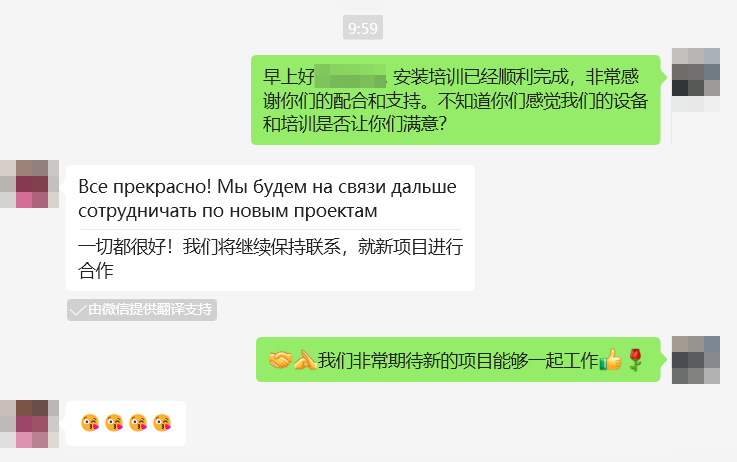

Highly evaluated by customers, laying the foundation for cooperation

The Russian customer expressed high appreciation after the equipment operation and training. The customer representative said: “The equipment supplied by Shanghai Duomu Industry Co., Ltd is excellent in terms of technical performance and ease of operation, which has improved the efficiency and product quality of our production line. At the same time, the training service of the technical team is meticulous and thoughtful, helping us to realize independent operation and maintenance quickly. This cooperation gives us full confidence in our future in-depth cooperation.”

Contributing to the international layout and deepening global market influence

The successful delivery of this project not only reflects our technical strength in the field of industrial automation equipment, but also further consolidates its brand position in the international market. Russia is an important market for industrial manufacturing, and the equipment and service of Shanghai Duomu Industry Co., Ltd have won the trust of local customers, and laid a good foundation for the subsequent development of more cooperation opportunities.

In the future, Shanghai Duomu Industry Co., Ltd. will continue to be committed to technological innovation and quality service, through the continuous introduction of high-quality intelligent manufacturing solutions, to create greater value for global customers. At the same time, the company will actively layout the global market, and promote the globalization of industrial automation welding and cladding technology.

Post time: Dec-31-2024