Screw propellers are widely used in many industries, such as brick reamers in brick factories, internal screw feeders in solid-liquid separation centrifuges, propelling screws in extruders and so on.

In the friction parts of the surface of the workpiece surfacing a layer of special properties of Taiwan gold, the purpose of which is to improve the surface of the anti-scratch, corrosion, erosion and high temperature resistance and other comprehensive performance, not only reduces the cost, but also improves the service life of the workpiece.

Wear reason analysis: screw propeller usually work in the acidic and alkaline production environment, the surface contact material hard and viscous class are available, long-term feeding process, the surface will be friction and corrosion, acidic and alkaline conditions will also produce galvanic corrosion and so on.

Spiral Thruster Vulnerability Solutions - Remanufacturing Methods

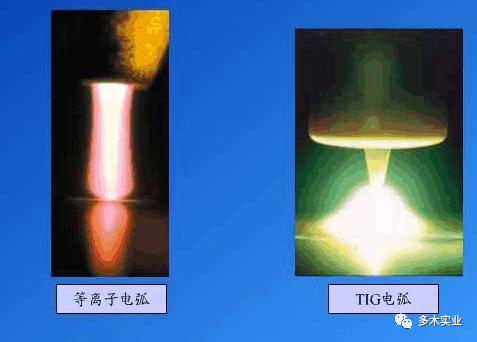

The surfaces of screw propellers are generally manufactured by overlay welding. The materials used for surfacing are categorized into four main groups according to the type of alloy, i.e. cobalt-based alloys, nickel-based alloys, iron-based alloys and copper-based alloys. These alloy materials are made into electrodes, wires (including flux cored wire), flux (including transition alloy type flux) and alloy powder, etc., using manual arc welding, oxy-acetylene flame welding, tungsten argon arc welding, submerged arc welding and plasma arc welding and other methods of cladding, where we mainly introduce plasma cladding cladding process.

Advantages of Plasma Surfacing

Plasma cladding due to the use of plasma arc as a heat source and the use of alloy powder as filler metal, thus compared with other surface cladding methods, has many advantages.

(1) Fast cladding speed, high productivity.

(2) Controllable melting depth, low dilution rate.

(3) Surfacing surface is flat and smooth, high density, can realize 0.5-5mm surfacing surface at one time.

(4)Good process stability, high quality spray welding layer, can be a long time continuously obtain stable surfacing layer, and surfacing surface without porosity, trachoma and other surfacing quality problems.

(5) Alloy powder preparation is simple, the use of a wide range of materials, can choose cobalt-based, nickel-based, iron-based, copper-based and other powder welding consumables, and can be directly formulated according to the working conditions.

(5)Can be equipped with special machines, robots, etc., according to demand, easy to realize automation, reduce labor intensity.

Plasma Surfacing System for Spiral Reinforcement--Duomu Products

This spiral brick machine plasma cladding machine is specially designed for brick factory brick machine reamer, the dislocator plus cross plus oscillator, can realize the plane cladding and spiral cladding, is a cost-effective equipment. At present, in the industry of brick machine repair, in North China, Western region customers like this set of equipment, cost-effective and high.

Screw Plasma Surfacing Machine

Plastic screws are commonly used in the production of rubber and plastic machinery wear parts, this set of equipment is widely used in screw repair and surface coating enhancement, but also can repair the shaft workpiece. In the screw repair, Zhoushan and Guangdong and other places for this equipment is in great demand, and we also have a loyal customer base.

Horizontal Vertical Surfacing Machine

In the solid-liquid separation industry, the special working environment of centrifuges as well as the special structure of the internal screws, two sets of cladding equipment are usually used for repair and strengthening. At present, the customers in the relevant industries very much agree with this horizontal and vertical cladding program.

Post time: Feb-22-2024