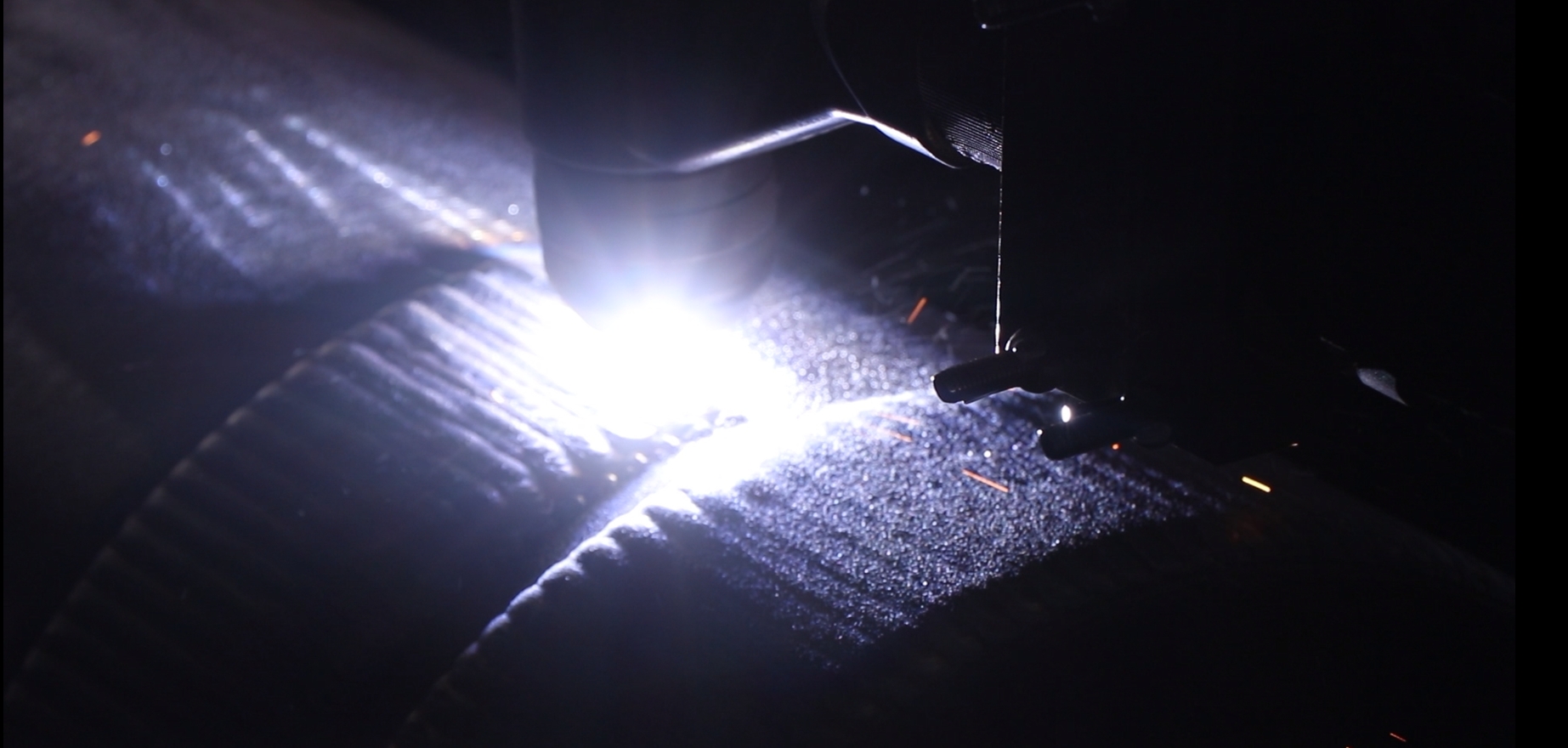

Plasma Transfer Arc Welding, commonly referred to as PTA or PTAW, is a heat-sourced material cladding process based on the principle of the plasma arc. The core of the process lies in the use of a high-temperature plasma arc (up to 15,000°C) to melt and metallurgically bond powdered metal materials to the surface of the substrate, thereby forming functional coatings with high hardness, wear resistance or corrosion resistance. Plasma Transfer Arc (PTA) welding is the natural evolution of the GTAW process and compensates for the lack of automation of conventional tungsten arc welding (GTAW) and tungsten inert gas shielded (TIG) welding machines.

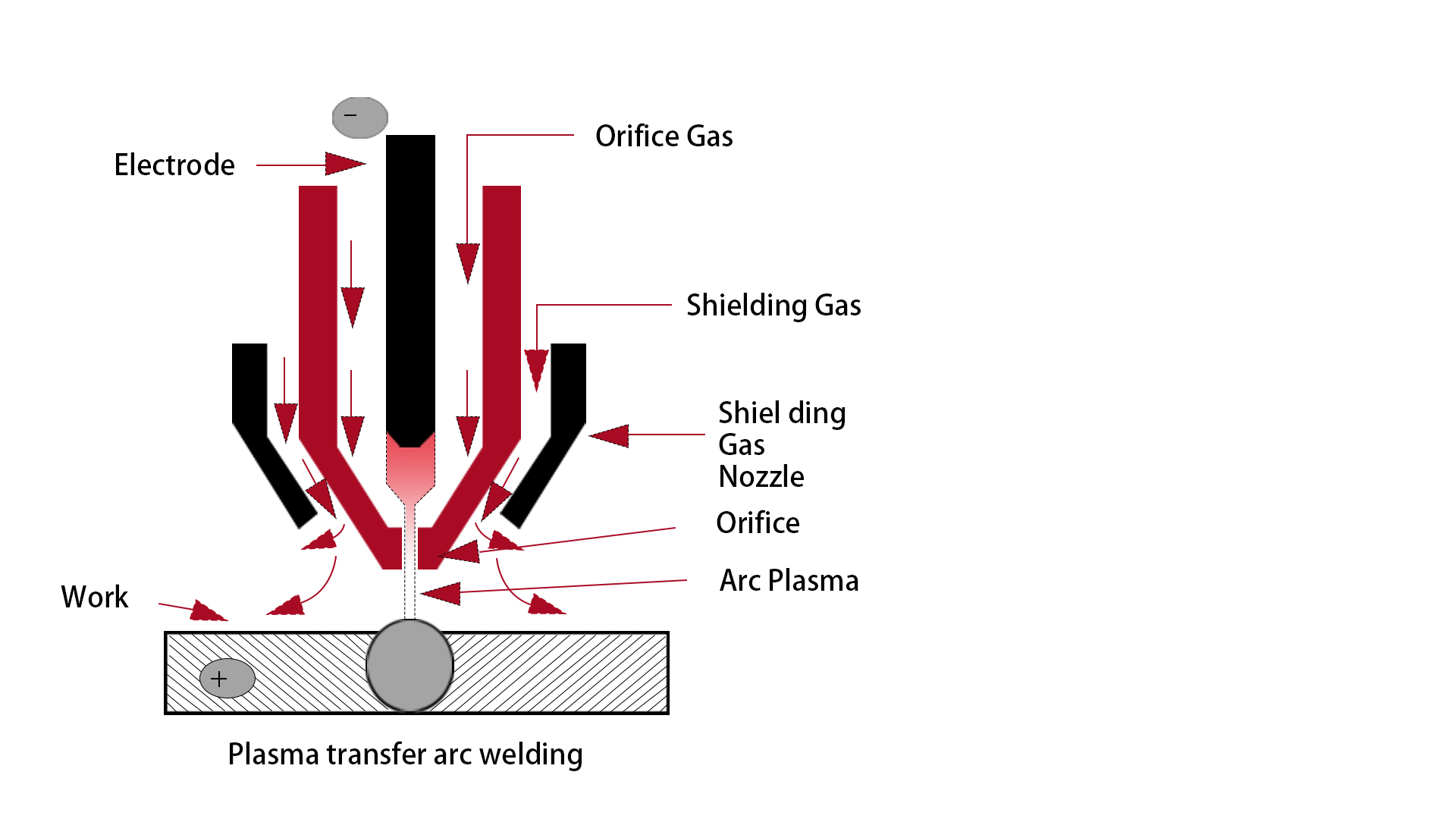

Working Principle of Plasma Transfer Arc Welding

Based on the action of a high-temperature heat source of a plasma arc, the plasma cladding material (metal or alloy powder) is melted and metallurgically bonded to the surface of the substrate to form a reinforcing coating, and a guided arc (non-transferring arc) is formed by applying a small electric current between the tungsten electrode and the nozzle. Under the action of the high-temperature arc an inert gas (usually argon) is ionized to form a high-temperature, high-density plasma stream. Essentially, the plasma is confined to high temperatures, high jet velocities and high energy densities.

What is the difference between PTAW and other welding techniques?

The basic principle of all welding techniques is to heat the material by means of a heat source, causing it to melt and form a weld or coating. But Plasma Transfer Arc Welding is closest in principle to the GTAW method because they both use non-consumable tungsten electrodes.The PTA welder has been redesigned to divert the pilot arc away from the torch in order to be throttled through a finely perforated copper nozzle, resulting in a higher energy density. PTA welding is more focused on surface strengthening and repair than conventional welding methods, while other welding methods (e.g. TIG, MIG, laser welding) are more focused on joining and structural component welding. To see a more detailed comparison, click.

Common Materials for PTA Welding Overlay

• Iron-based alloys

• Nickel-based alloys

Inconel 625

Inconel 718

more

• Cobalt-based alloys

Stellite 6

Stellite 12

more

• Chromium-based alloys

CR20

CR25

more

• Tungsten carbide

PTA Welding Surfacing Solutions

The core reasons for choosing PTA weld overlay solutions are due to their high precision, superior cladding quality, high material utilization (>90%), automation capabilities and multi-material adaptability. Compared to SMAW, GMAW, TIG and other welding technologies, PTA welding excels in wear and corrosion resistant coating scenarios, combining performance and cost advantages.

Application Areas

• Petrochemicals

• Metallurgy

• Aerospace

• Automotive

• Energy

• Medical, etc.

Choosing the right PTA weld overlay

In Shanghai Duomu Industry Co., Ltd.We have introduced a variety of equipment and solutions for PTA welding overlay welding, the company has an independent R & D organization to ensure the practicality of the product, stability and technology of the continuous updating and leading products based on advanced DSP control technology (high-speed, high-precision, anti-jamming ability of the digital signal processing technology) development, superior performance plasma transfer arc welding series has reached the industry's advanced level. Interested in our PTA welding equipment? Want expert advice on the industry's top PTA welding and cladding solutions? Contact us!

Post time: Jan-16-2025