With the continuous development of aerospace technology and increasingly stringent performance requirements for key components, plasma cladding technology, as an advanced surface engineering technology, is becoming a key means to enhance the performance and reliability of aerospace vehicles. In recent years, the wide application of this technology in the core areas of aviation engines, turbine components, combustion chambers, etc. is leading the technological innovation of the industry.

Plasma cladding technology melts and precisely sprays metal or ceramic materials onto the surface of the substrate through a plasma arc to form a coating with excellent performance. The application of this technology in the aerospace field greatly improves the high temperature, wear and oxidation resistance of components, providing a strong guarantee for the safety and durability of aircraft.

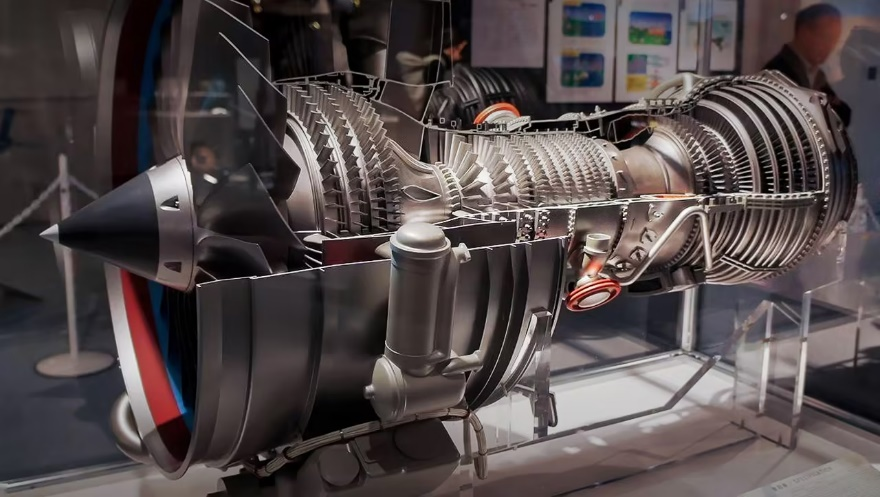

Enhancing the high-temperature performance of aero-engine turbine blades

Aero-engine turbine blades operate at extremely high temperatures and face severe material challenges. Plasma cladding technology provides high-temperature resistant coatings for turbine blades, significantly enhancing their oxidation and wear resistance. In this way, the operational efficiency of the engine is improved and the service life of the blades is significantly extended. This not only reduces maintenance costs, but also improves the safety and economy of the vehicle.

Reliable thermal barrier protection for combustion chambers

The high-temperature environment in the combustion chamber of an aero-engine places high demands on the heat resistance of materials. The thermal barrier coating formed on the inner wall of the combustion chamber by plasma cladding technology effectively reduces the temperature of the substrate and prevents direct erosion by high temperature gases. The application of this technology improves the durability and combustion efficiency of the combustion chamber, providing a reliable guarantee for the efficient and stable operation of the engine.

Strengthening the wear resistance of turbine disk and turbine shaft

Turbine disks and turbine bearings of aero-engines are subject to huge centrifugal force and wear, and the wear-resistant coatings formed on the surface of these parts by plasma cladding technology significantly enhance their wear-resistant performance and reduce the wear and damage in long-term operation. In addition, plasma cladding can be used to repair these high-value components, restoring their original performance, extending their service life and reducing overall operating costs.

Advancing the Remanufacturing and Functionalization of Aerospace Components

With the focus on sustainability in the aerospace industry, plasma cladding technology shows great potential for component remanufacturing and surface functionalization. Not only can the technology repair and remanufacture decommissioned components, but it can also optimize specific functions, such as tribological properties and electrical conductivity, through the application of functional surface coatings to meet the needs of complex applications.

Leading Aerospace Technology Innovation

Plasma cladding technology, with its unique advantages, is driving profound changes in the aerospace field. The overall performance of aerospace vehicles has been significantly improved through the wide application of plasma cladding on key components. In the future, with the continuous progress of technology, plasma cladding will play a greater role in a wider range of applications, helping the aerospace industry to move to new heights.

About Us

ShanghaiDuomu is a leading global provider of surface engineering solutions, specializing in the development and application of plasma cladding, thermal spraying and other advanced technologies. We are committed to providing innovative surface treatment technologies for the aerospace, energy, and automotive sectors, helping our customers realize superior performance and economic benefits.

Post time: Aug-28-2024