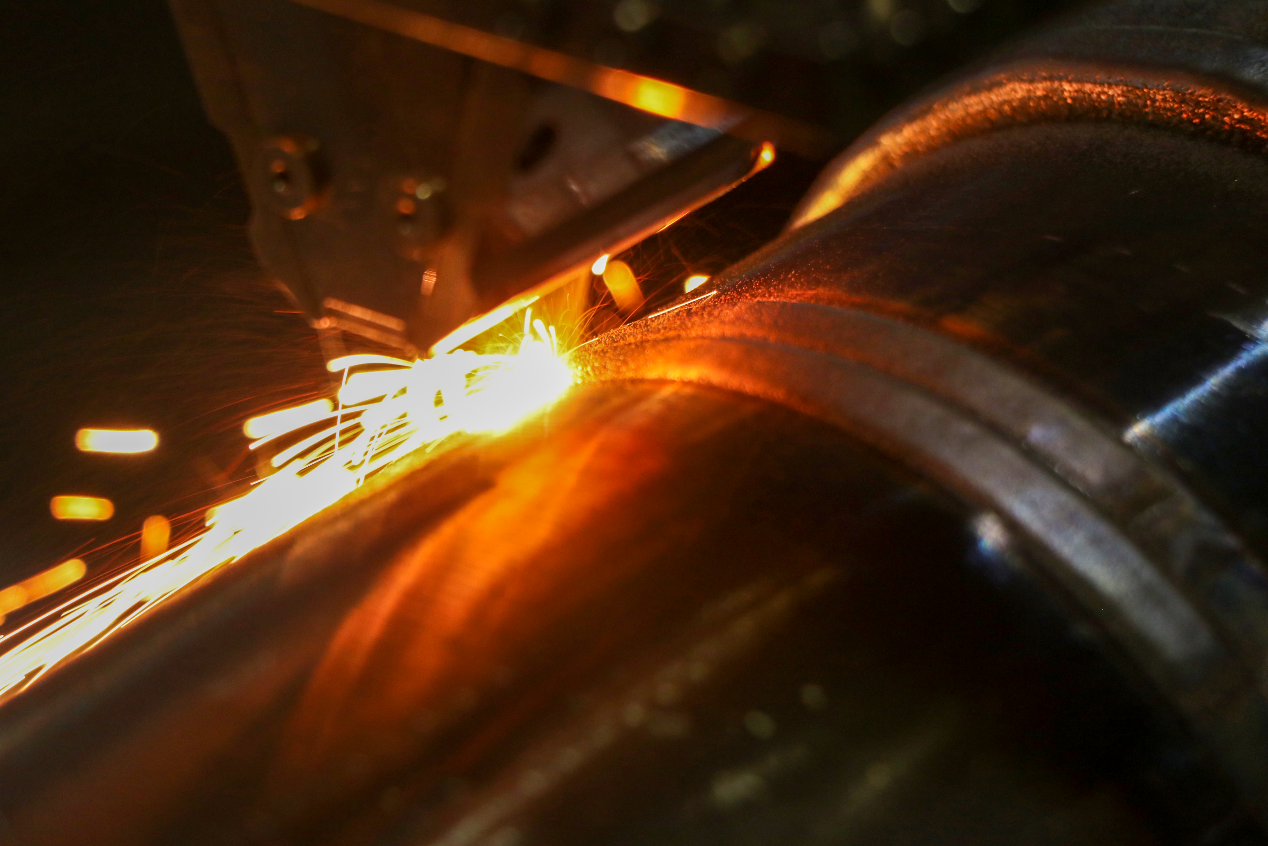

With the continuous progress of manufacturing technology, laser welding, as an efficient and precise welding technology, is being widely used in various industries. In particular, two methods, frame welding and synchronous welding, are driving the continuous improvement of manufacturing processes with their excellent performance and wide applicability.

Frame Welding: The solution for high-precision structural welding

What is frame welding?

Frame welding is a laser welding method mainly used to weld joints and nodes of frame structures. It uses a laser beam to precisely weld different parts of the frame, ensuring high strength and stability of the frame structure.

- High-strength joints: laser welding creates deep-melt welds that ensure the strength and durability of frame structures.

- Precise control: The high-precision control of laser welding results in precise dimensions and shapes of welded parts.

- Low heat distortion: Due to the small heat-affected zone of laser welding, the deformation of the frame structure is extremely small, which ensures the dimensional accuracy of the product.

Frame welding is widely used in the following fields:

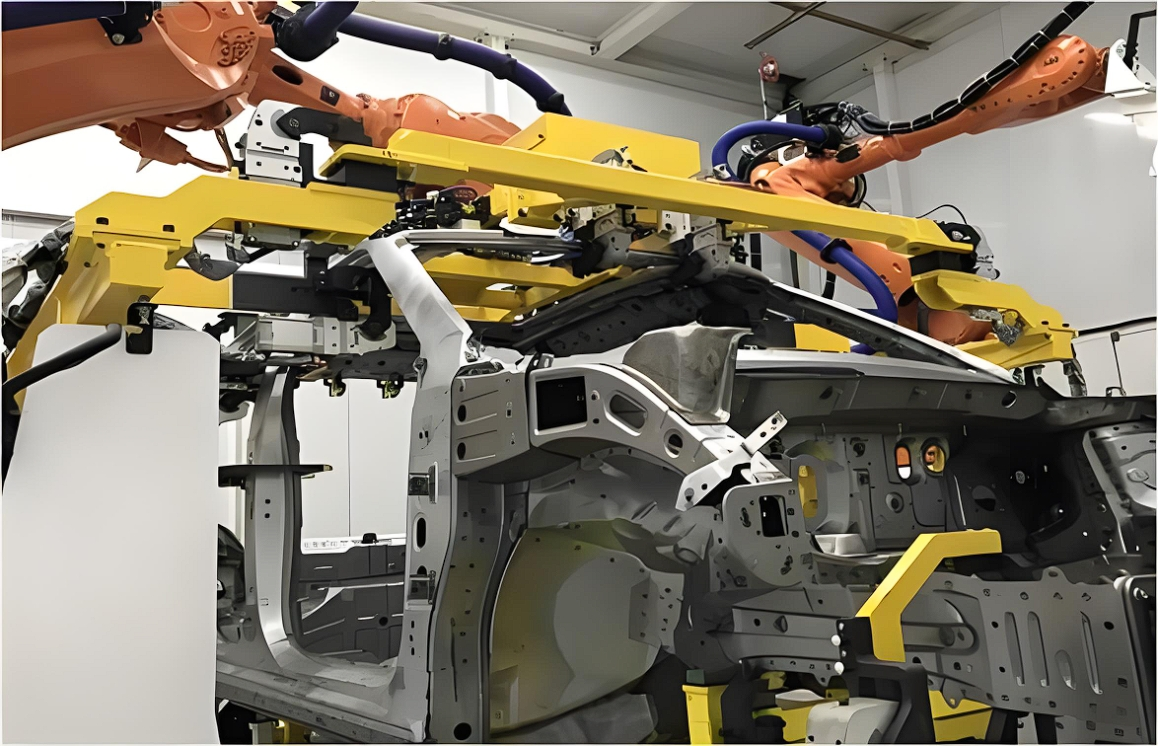

1. Automobile manufacturing: Welding of body frames and chassis to ensure the structural strength and safety of vehicles.

2. Aerospace: Welding of aircraft structures and body frames to improve the structural stability and reduce the weight of the vehicle.

3. Construction: Welding of building steel structures to increase the seismic resistance and durability of buildings.

Example: A car manufacturer uses laser frame welding technology to weld body frames. Compared to conventional welding methods, the strength of the frame was increased by 15 per cent and the manufacturing cycle was reduced by 20 per cent.

Synchronous Welding: Efficient Multi-Point Synchronous Welding Technology

What is synchronous welding?

Synchronous welding is a welding method in which multiple laser beams are applied to multiple welding points at the same time. It can weld multiple parts at the same time for an efficient and fast welding process.

Features of simultaneous welding

- High efficiency: Multiple laser beams act simultaneously, dramatically increasing welding speed and efficiency.

- Uniform heating: multiple points are heated at the same time, reducing thermal stress and deformation, welding quality is uniform and consistent.

- Process simplification: reduces the process steps in the welding process and improves the automation of the production line.

Synchronous welding is suitable for occasions where fast and efficient welding is required, and is mainly applied to:

1. Electronic products: welding of electronic components and circuit boards to improve product productivity and welding quality.

2. Medical devices: welding of high-precision medical devices, such as minimally invasive surgical instruments and implantable devices, to ensure product reliability and safety.

3. photovoltaic industry: solar panel connection welding, improve the productivity and stability of photovoltaic modules.

Case: An electronics manufacturer introduced laser synchronous welding technology to weld electronic components. Compared with the traditional welding method, the welding efficiency has been increased by 30%, the welding quality has been significantly improved, and the production cost has been reduced by 15%.

About Shanghai Duomu

Shanghai Duomu is a high-tech enterprise focusing on the research, development and application of advanced welding technology. We are committed to providing customers with efficient and precise welding solutions, and promoting the manufacturing industry to achieve high efficiency, automation and precision development. Through continuous innovation, we have accumulated a wealth of experience in the field of laser welding and become a leading technology provider in the industry.

Laser welding technology, especially frame welding and simultaneous welding, is becoming an indispensable process tool in the manufacturing industry with its unrivalled efficiency and precision. In the future, with the continuous progress of technology, laser welding will show its strong application potential in more fields, injecting new vitality for the innovation and development of manufacturing industry.

For further information about laser welding technology and its applications, please feel free to contact us!

Post time: Jul-01-2024