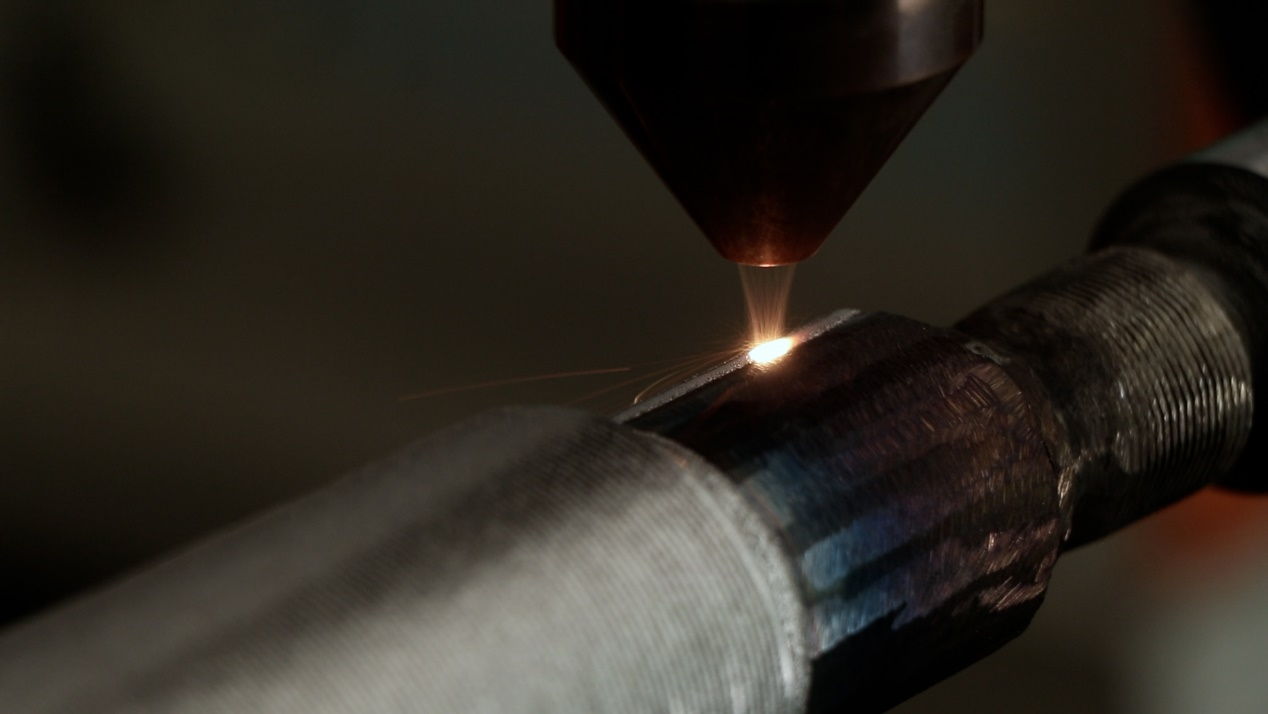

As a key component of mechanical equipment, the performance of shaft parts directly affects the operational efficiency and service life of the equipment. Traditional surface treatment methods are often difficult to meet the growing industrial demand in the face of high strength, high wear and complex working conditions. The emergence of surface cladding technology provides a brand new solution to this problem.

Surface cladding technology by cladding a layer of high hardness, high wear resistance and corrosion resistance material on the surface of the shaft parts, so that its surface performance is greatly improved. This technology not only extends the service life of shaft parts, but also greatly reduces maintenance costs and downtime. The application of surface cladding technology is particularly promising in demanding industries such as aerospace, automobile manufacturing, heavy machinery and energy.

Technical Advantages

1. **Significantly improve the wear resistance and corrosion resistance**: the selection of materials and process control of the cladding layer enables the shaft parts to operate stably for a long time in harsh working environments.

2. **Extend service life**: The service life of shaft parts treated by cladding technology can be increased by 2-3 times, which reduces the need for frequent replacement of parts.

3. **Reduced maintenance costs**: Long-life coated shaft parts significantly reduce the number of maintenance and downtime of the equipment, thus reducing the overall operating costs.

4. **Environmental protection and energy saving**: The application of cladding technology reduces the consumption of resources and the generation of waste, which is in line with the current trend of green manufacturing.

Industry Application

The successful application of surface fusion cladding technology has benefited from the close cooperation between manufacturing enterprises and scientific research institutions, which have jointly overcome a series of technical difficulties.

In the field of automobile manufacturing, the application of surface cladding technology has also achieved remarkable results. A large automobile manufacturer through the engine crankshaft cladding treatment, significantly improve the engine wear resistance and anti-fatigue performance, and further optimize the performance of the vehicle.

Outlook for the future

With the continuous development and improvement of surface cladding technology, its application scope will be more extensive and the technical level will be more mature in the future. Manufacturing enterprises will further increase R & D investment, and continue to explore new materials, new processes, and promote the surface cladding technology to a higher level.

The popularization and application of surface cladding technology not only brings a new solution for the manufacturing of shaft parts, but also injects new vitality into the whole manufacturing industry. We believe that with the continuous progress of this technology, the manufacturing industry will usher in more innovation and change in the future.

About Us

Dedicated to innovation and technological breakthroughs, Shanghai Duomu Industrial Co., Ltd. specializes in the research, development and manufacturing of high-performance mechanical parts. With advanced technology and excellent quality, the company provides global customers with high-quality products and services, and helps various industries to realize sustainable development.

Post time: May-30-2024