Plasma Arc Welding (PAW) and Gas Tungsten Arc Welding (GTAW, also known as Tungsten Inert Gas Shielded Welding, TIG Welding) have many process similarities, but they also have some significant differences. The following are the major differences:

1. Arc formation method

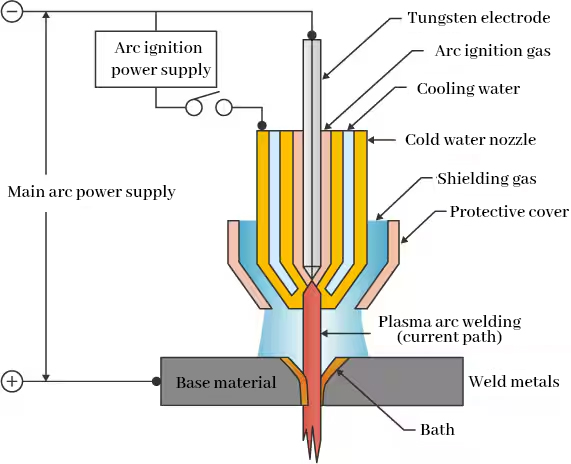

- Plasma Arc Welding (PAW): PAW uses a controlled plasma arc that is generated by ionized gas inside the torch and compressed through a small nozzle. Because the arc is confined by the nozzle, the arc is more concentrated and has a higher energy density. These plasma arcs can be categorized into two types: **Non-transferred Arc** and **Transferred Arc**. The non-transferred arc is used to stabilize the welding process, while the transferred arc is used to weld the material.

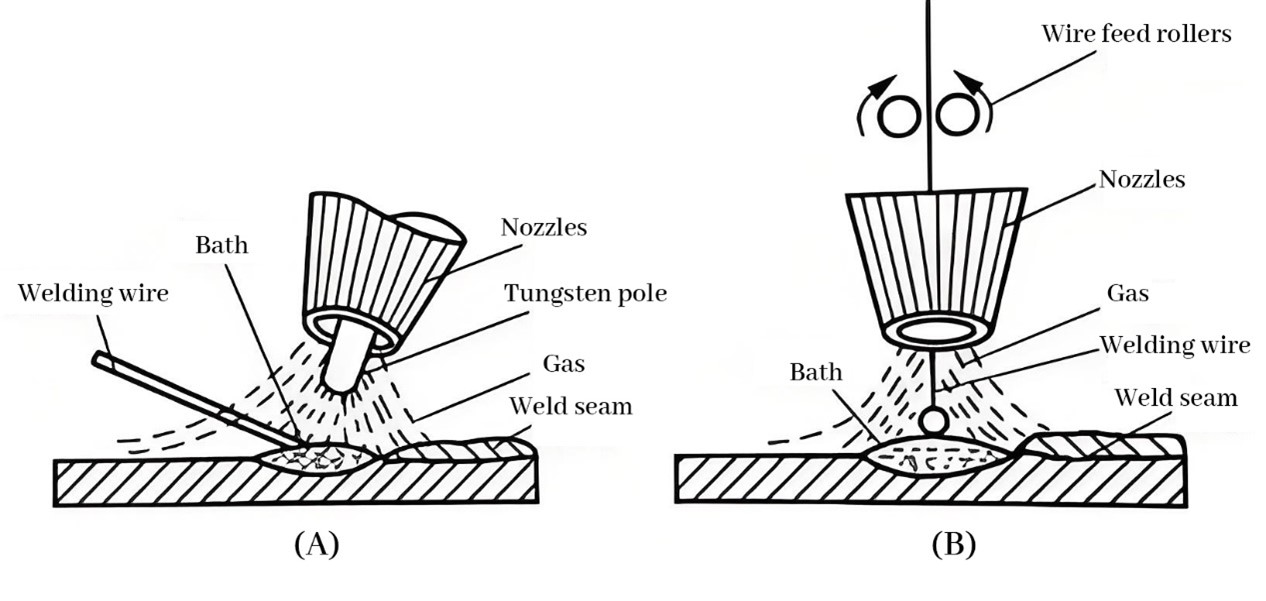

- GTAW (TIG Welding): GTAW uses a non-molten tungsten electrode to produce an arc, which is applied directly to the welded workpiece and is not compressed by the nozzle. This arc has a more natural and dispersed shape.

2. Arc precision and energy density

- PAW: The plasma arc is compressed by the nozzle, the arc is more concentrated, the energy density is higher, the welding penetration is stronger, suitable for precision welding of thicker materials. In addition, PAW produces a narrower weld seam and deeper depth of fusion.

- GTAW: The arc of GTAW is broader, with relatively low energy density, suitable for welding thin materials. Its weld control is better, but the penetration ability is not as good as PAW.

3. Protective gas

- PAW: PAW uses two gases: ** ion gas ** and ** shielding gas **. The ionizing gas (usually argon) is used to form the plasma arc and the shielding gas (such as argon or helium) is used to protect the weld zone from oxidation.

- GTAW: GTAW usually uses only one inert gas (e.g. argon or helium) to protect the weld area from atmospheric oxygen and nitrogen reacting with the molten pool.

4. Electrodes

- PAW: The tungsten electrode in PAW is surrounded by a nozzle and the electrode is not directly exposed to the weld area, resulting in longer electrode life and a more stable welding process.

- GTAW: In GTAW, the tungsten electrode is exposed to the weld area and is susceptible to contamination and wear and tear, thus requiring frequent maintenance and replacement of the electrode.

5. Application Scenarios

- PAW: Due to the high energy density and concentration of the plasma arc, PAW is suitable for thicker materials, precision welding and high productivity applications, especially used in aerospace, nuclear industry and welding of thick-walled stainless steel pipes.

- GTAW: GTAW is suitable for precision, low heat input welding, and is used especially in thin materials and demanding welding (e.g. aluminum, magnesium, stainless steel, etc.). It is ideally suited for the manufacture of precision parts and small welding operations.

6. Operating Difficulty

- PAW: Due to the use of a compressed plasma arc, the operation is relatively more complex and the cost of the equipment is higher, but it offers higher welding speeds and deep melting capabilities.

- GTAW: GTAW is relatively simple to operate and the equipment is relatively inexpensive. It is one of the most common processes used in manual and automatic welding.

Summary

Plasma Arc Welding (PAW) and GTAW are similar in principle in that they both generate an arc through a tungsten electrode and protect the weld with an inert gas, but the PAW arc is compressed and the energy is more concentrated, which makes it suitable for thicker materials and high-precision welding, whereas the GTAW is more suited to welding thin materials with a low heat input. The two are different in terms of weld thickness, energy density, type of shielding gas, and difficulty of operation.

Post time: Sep-29-2024