Discussion on powder feeding mode of laser cladding

Laser cladding is a new technology for manufacturing and repairing reinforced metal parts, which has been widely used in aerospace, automobile manufacturing, petrochemical and other fields. As one of the core components of the cladding equipment, the performance of the powder feeder will directly affect the quality of the cladding layer, and it has increasingly become the focus of attention. At present, there are two common powder feeding methods for laser cladding: preset powder feeding method and synchronous powder feeding method.

Preset powder feeding mode

The alloy powder material to be coated is covered on the surface of the base material in advance, and then the laser beam is used to scan the surface of the alloy pre coating layer. The surface of the pre coating layer absorbs the laser energy to raise the temperature and melt. At the same time, the surface heat is transferred to the inside through heat conduction. After the laser beam leaves, the molten metal rapidly solidifies on the surface of the substrate, forming a metallurgically bonded alloy cladding layer. It has the advantages of high efficiency, uniform coating thickness and firm combination with the substrate, but the disadvantages are low powder utilization rate, requiring special equipment and technology.

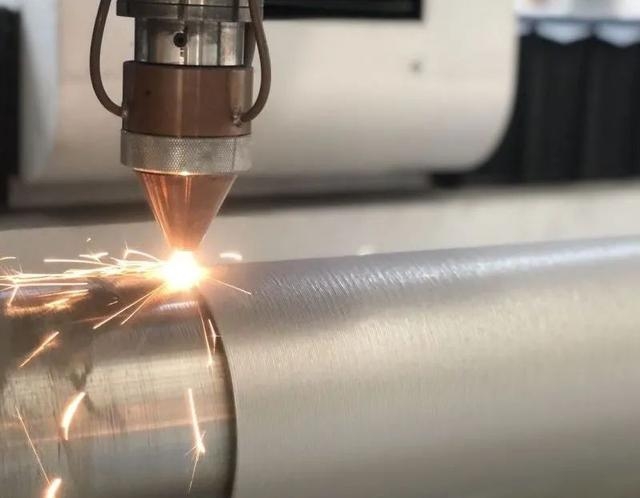

Synchronous powder feeding mode

The alloy material is directly sent to the laser action zone by a special conveyor. Before reaching the melting zone, the powder passes through the beam and is heated to a red hot state. After falling into the melting zone, it melts immediately, and is sent with the base material and powder to form an alloy cladding layer. Synchronous powder feeding methods include synchronous lateral powder feeding and coaxial powder feeding. Synchronous lateral powder feeding is simple in structure and low in price, but the powder utilization rate is not high and the cladding quality is relatively poor. It can be applied to laser cladding of plane and axis. The coaxial powder feeding structure is complex, the powder is preheated, the cladding quality is good, and the versatility is strong.

With the rapid development of laser cladding technology and the improvement of processing accuracy and quality requirements of cladding layer, it is particularly important to develop high-performance powder feeder for laser cladding processing.

Post time: Aug-24-2022