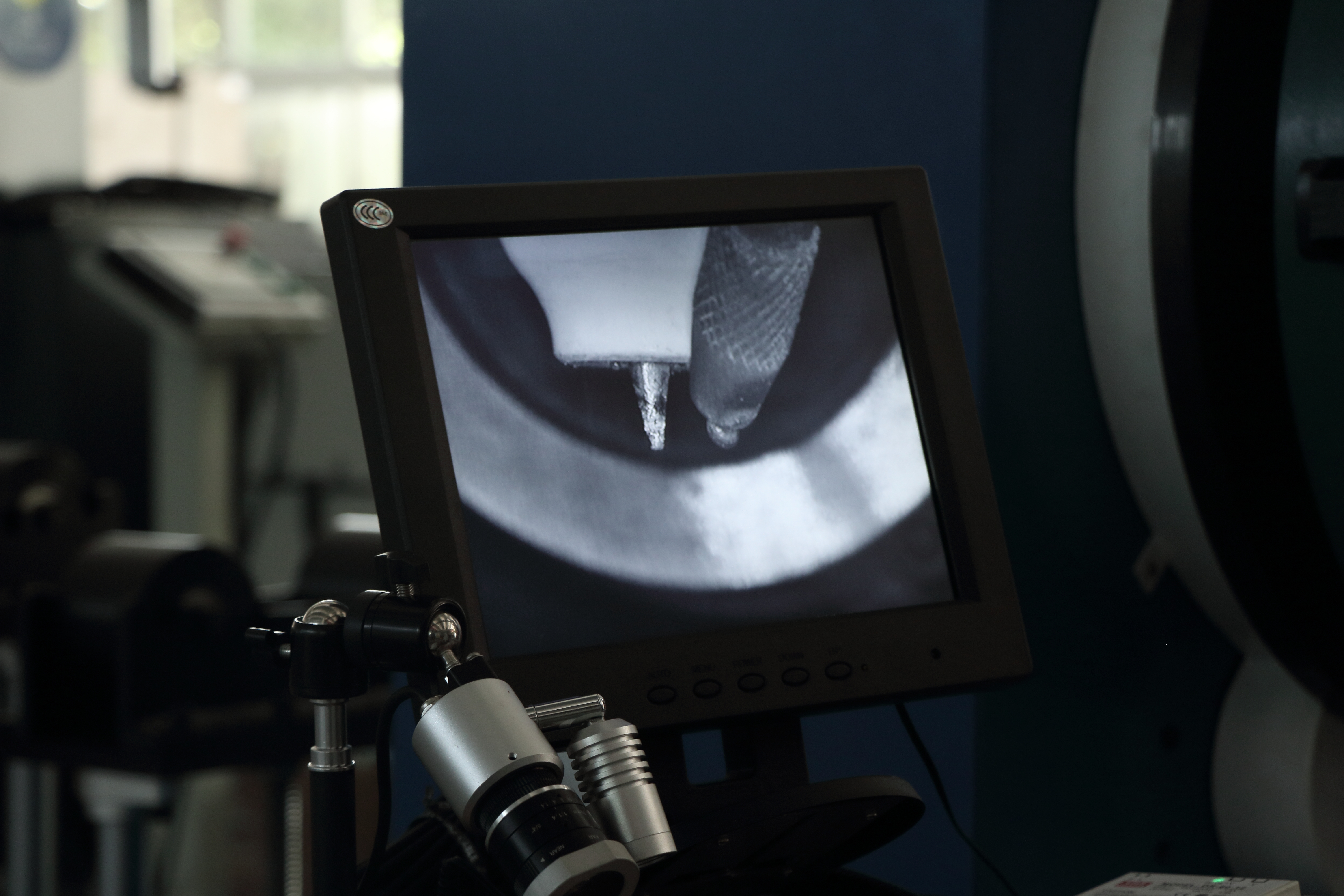

Plasma cladding is a highly efficient metal surface strengthening technology, which deposits cladding materials onto the surface of a workpiece through a plasma arc, thereby improving its wear resistance, corrosion resistance and high temperature performance. However, due to the high temperature, high brightness and complex process parameters of the cladding process, it is often difficult for traditional monitoring means to capture the details of the cladding process in real time and accurately. This release of the borehole camera is designed to address this challenge.

The borehole camera has the following outstanding features:

1.High-temperature tolerance: advanced high-temperature-resistant materials and cooling systems, able to work stably in environments up to 2000 ℃.

2.High Definition Imaging: Equipped with a high resolution sensor, it can provide clear and detailed images in extreme environments, helping technicians accurately monitor the welding process.

3.real-time monitoring: supports real-time video transmission and recording, enabling operators to instantly detect and correct abnormalities in the process, improving productivity and product quality.

4.Intelligent analysis: integrated with advanced image processing algorithms, it can automatically analyze the quality of the cladding and generate detailed process reports, providing data support for process optimization.

5.Flexible adaptability: compact design, easy to install in a variety of complex workpiece bores, suitable for different sizes and shapes of workpieces.

The launch of this bore camera not only fills the gap in plasma cladding process monitoring technology, but is also a major technological innovation in the metal processing industry. Through this innovative tool, companies can better control the quality of cladding, reduce the defective rate, lower production costs, and enhance the market competitiveness of their products at the same time.

We believe that this bore camera will become an indispensable “eye” in the plasma cladding process, bringing unprecedented precision and reliability to the industry. We look forward to working with our partners to see the widespread use of this technology and to continue to push the boundaries of metalworking technology.

Post time: May-20-2024