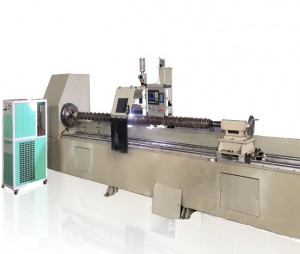

FB-200P Automatic plasma welding machine for valve

Equipment features

The mechanical walking structure adopts imported linear guide rail, precision worm gear reducer and stepper motor drive walking. The whole machine has small transmission clearance, high rigidity, stable and reliable operation, and convenient integration.

The unique middle through hole design of hbt-3 through hole welding positioner adapts to the overlaying welding operation of inner and outer circles of various super long shaft parts. The servo motor drives the slewing bearing to realize the precision transmission of the spindle, with small clearance, high rotation accuracy and convenient control.

Integrated structure, easy to transport and move.

CNC and PLC dual system integration, five axis linkage, for taper arc cylindrical products to complete the welding action at one time.

Equipped with lighting, exhaust fan, shading mobile protective door, simple operation, beautiful overall structure, humanized.

Applicable products

It is suitable for surfacing and repairing of wear-resistant layer of general shaft parts and pipe parts.It can also be used for surfacing and repairing of disc parts.

| Configuration items | Model and brand | Description of main parameters |

| Transverse mechanism motor | Research and control stepping motor | Effective stroke 1100mm |

| Lifting column motor | Research and control stepping motor | Effective stroke 650mm |

| Spindle rotating motor | Xinjie servo motor | The rotating speed is 0.01r/min ~ 5.0r/min |

| Welding positioner | HBT-3S | Rated load 300 kg |

| Three jaw chuck | K11-320C | The clamping range is 25-320 mm |

| Arc voltage tracking | Multi wood integration | |

| Current communication | 485 communication | |

| touch screen | Wellington | 7-inch screen tk6071iq |

| Control system | Mitsubishi, Japan | FX series PLC |

| Control panel | Multiwood manufacturing | Integrated on the equipment shell |

| Reference footprint | 2000mm*1200mm*2200mm | |