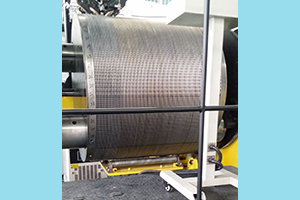

DMMP-01 Numerical control welding machine for heat exchanger diaphragm

Numerical control welding machine for heat exchanger diaphragm

The all welded plate shell heat exchanger is a new type of high efficiency heat exchanger which is suitable for high temperature, high pressure, corrosion resistance and other occasions. It is composed of shell, heat exchange plate group, inlet and outlet connecting pipe, flange, cover plate and support. It combines the advantages of detachable high efficiency and shell and tube high temperature and high pressure. Compared with the all welded plate frame type, it has higher temperature and pressure resistance,It is an effective alternative to shell and tube heat exchanger.The core component of the heat exchanger is the heat exchange plate group, and the welding quality of the plate group is the key factor of the heat exchanger. The plasma welding equipment developed by our company can effectively solve the welding process problems of the inner circle and outer circle of the plate group, and make outstanding contributions to the quality of domestic heat exchanger catching up with and exceeding the international standard.

Features of the machine:

1. It adopts the precision plasma welding power source independently developed by the company. The whole welding process is controlled by waveform. The welding process is stable and the dynamic quality of the power source is excellent.The output is controlled accurately.

2. Mitsubishi PLC is adopted.

3. LCD touch screen is adopted.

4. The welding power source is connected with the control system by communication, and the welding process parameters are controlled by program.

5. The welding process is forced cooling, and the deformation of welding product is small.

6. Inner hole welding: one clamping, automatic completion of double inner hole welding.

7. Outer circle welding: one clamping, automatically complete the whole welding process of the set length.

8. Welding depth, strong tensile strength and high pressure resistance.

9. High degree of automation, excellent welding quality.

Advantages of plasma surfacing

1.The results show that the cladding alloy layer is metallurgical bonding with the workpiece substrate, and the bonding strength is high;

2.The cladding speed is fast and the dilution rate is low;

3.The surfacing layer has compact structure and beautiful appearance;

4.It can directly carry out plasma surfacing on the surface of corroded and greasy metal parts without complicated pretreatment process;

5.The surfacing process is easy to realize mechanization and automation;

6.Compared with other plasma spray welding, the equipment is simple in structure, energy saving, easy to operate, and easy to maintain

Product application

It is suitable for the welding of inner circle and outer circle of diaphragm group of all welded plate shell heat exchanger.