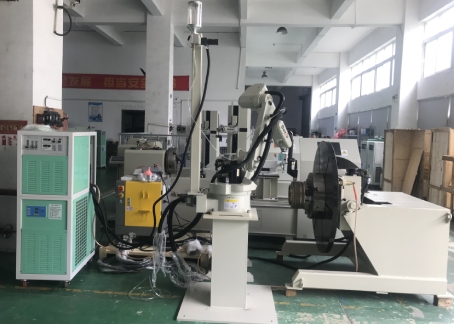

DH1440-B06 Automatic plasma surfacing robot

Characteristic

1.DSP digital processing technology is adopted, with high speed and precise control.

2.Unique digital inverter technology, stable current output, wide adjustment range.

3.High voltage design ensures smooth arc starting of welding machine.

4.High voltage design ensures the stiffness and length of arc.

5.Arc starting current and base value current are adjustable.

6.The arc current is adjustable (2-20a).

7.The rising and falling time of current is adjustable, and the gas delay time is adjustable.

8.The data storage module can store welding data in multiple channels, which is convenient to store and flexible to call.

9.Digital communication port, can realize remote control of welding (optional).

Equipment features

1.Highly integrated: main arc power supply, dimension arc power supply, powder feeding control system and refrigeration system are highly integrated.

2.High power refrigeration: up to 2p refrigeration system, to meet the system's long-time, high load work cooling needs.

3.Integrated design, programmed control, convenient and flexible operation.

4.Automatic powder feeding, manual powder feeding, advanced powder feeding and delayed powder feeding can be selected flexibly.

5.The integrated design simplifies and optimizes the layout and connection of all parts of the equipment to reduce the failure rate.

6.Equipped with die-casting high-power stack welding gun.

Welding parameters

|

Welder model |

DML-03 |

|

|

Pulse welding |

Continuous welding |

|

|

Dimensional arc current IP (a) |

3-20 |

3-20 |

|

Welding current I1 (a) |

2-160/300 |

2-160/300 |

|

Base current I2 (a) |

2-110 |

|

|

Current rise time T3 (s) |

0-2.0 |

0-2.0 |

|

Current drop time T4 (s) |

0-2.0 |

0-2.0 |

|

Pulse welding time T1 (MS) |

1-999 |

|

|

Welding interval T2 (MS) |

10-990 |

|

|

Gas protection time (s) |

1.0-20.0 |

1-20.0 |

|

Input voltage (V) |

Three phase 380 V, 50 Hz AC |

|

|

Rated input power capacity (kVA) |

8(160A)/16(300A) |

|

|

Output current regulation range (a) |

1-160/1-300 |

|

|

Load duration rate (%) |

60% |

|

|

Ion gas flow rate (L / min) |

0.2-1 |

|

|

Protective gas flow (L / min) |

1-12 |

|

|

Weight (kg) |

82 |

|

|

Overall dimension (mm) |

695*375*665 |

|

Product application

1.Steel, coal industry: cold (hot) roll, middle groove, wear-resistant plate, pick, etc.

2.Electric power, cement industry: steam turbine blades, grinding roller, etc.

3.Petroleum and chemical industry: surfacing of drill pipe, drill bit, valve, etc.

4.Construction machinery, mining machinery industry: rotary digging teeth of shield machine, roller sprocket, excavator bucket teeth, crawler shoes, etc.

We can provide a complete set of automation solutions according to customers' needs.