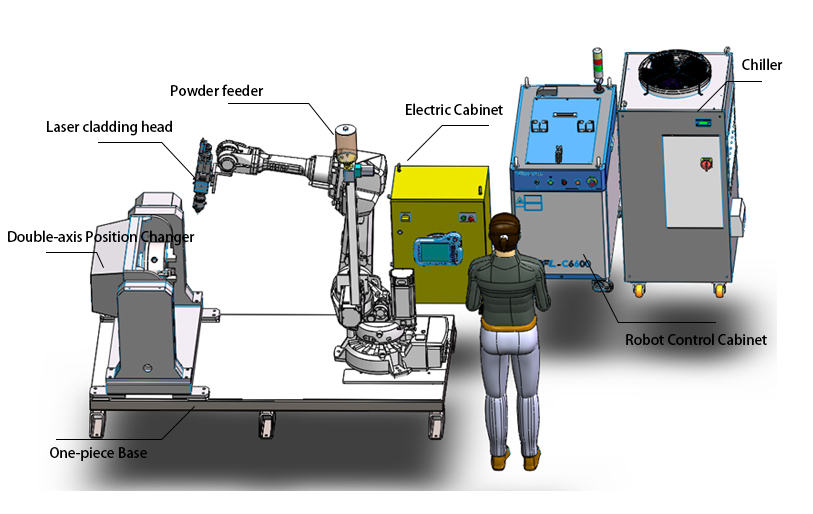

Automated laser cladding machine

Working Principle

Laser cladding technology utilizes a high-energy laser beam to melt and adhere the cladding material (e.g. powder or wire) to the surface of the workpiece. After cooling, a dense cladding layer is formed. This process enhances the wear, corrosion and high temperature resistance of the workpiece.

Equipment Overview

Equipment Parameter

|

Parameters |

||||

| Item | Model | Qty | Brand | Note |

| Laser | RFL-C6000 | 1 | Raycus | 6000w |

| Laser Chiller | TFLW-6000WDR | 1 | Tongfei | / |

| Laser Torch | TS-8.20A | 1 | Duomu | / |

| Powder Feeder | DM-S03 | 1 | Duomu | / |

| Robot Arm | KR70 2100 | 1 | KUKA | Arm Span 2100mm |

| Robot Control Cabinet | KR C5 | 1 | KUKA | / |

| Robot Remote Control | KUKA smartPAD | 1 | KUKA | / |

| Control System | PLC | 1 | Duomu | / |

| Double-axis Position Changer | HB-50 | 1 | Duomu | Load Capacity 500kg |

| Chuck | K21-320 | 1 | Huantong | Max. clamping dia:320mm |

| One-piece Base | Customized | 1 | Duomu | / |

| Overall Equipment Footprint | 5x3m,Height 1.8m | |||

Laser cladding advantage

1.High precision: fine focusing of the laser beam, precise control of the thickness and shape of the cladding layer.

2.Material versatility: a wide range of materials can be melted and clad, such as alloy, stainless steel, cobalt-based, nickel-based, and so on.

3.Low heat input: reduce workpiece deformation, suitable for high precision parts.

4.High degree of automation: improve production efficiency and reduce the risk of manual operation.

Product Applications