The Overview of Micro Plasma Welding Equipment for Medical Guide Wire

Medical guide wire applied for treatment of vascular diseases, which possesses controllability and suppleness as well as reductibility. When the head need going into the tortuous blood vessel, the wire rod should be flexible for going through smoothly. It is necessary for the head to be proper hardness and fine tactile feedback. Meanwhile, the catheter as a high value-added guide wire is the main tool of dermal puncture and cannula.

Generally speaking, the medical wire is welded by the end of coil and the core of wire, after welding, the welding spot of head would be high breakage joint strength to conventional welding way of soldering.

Plasma welding is the approach of end ball seal welding, belonging to touch welding. However, the our machine micro plasma welding DML-V01S would resolve the problem of hardness to control of the head forming, the solder joint is too long and of arduous remove impurity away.

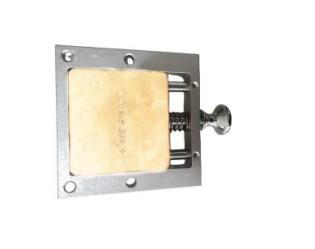

This set of micro plasma welding system covered the power supply, fixture, controller, torch, tooling. It is researched and developed especially for medical guide wire.

1 Concentrated energy, high temperature, fast welding speed. The arc column has good straightness, is insensitive to changes in arc length, and has good arc stability. Good welding quality and many weldable materials.

2 The technolosy of dual power DC voltage stabilizing moudule, arcing 0.1 A, has a higher continuous load rate to avoide the overload problem. It is superior to the single power cold welding machine in the market.

3 The tooling is controlled by PLC, which has good convenience.

4 The special tooling for wire guide can meet the requirements of 0.032、0.035and 0.038 inches in outer diameter of the guide wire.

Equipment Overview:

Post time: Mar-30-2023