Valves and gates have extensive applications in the industrial sector, playing a crucial role in controlling fluid flow in machinery and piping systems. However, these components often face challenging environmental conditions such as high temperatures, pressures, and corrosive agents, leading to surface wear and corrosion that can impact their performance and longevity. To address these issues, welding-based cladding techniques are commonly employed.

Cladding through welding is a repair technique that involves depositing a protective layer of material onto the component's surface, providing wear resistance, corrosion resistance, or high-temperature resistance. For valves and gates, welding-based cladding is an effective method to restore their surface properties, extend their service life, reduce maintenance costs, and enhance equipment reliability and safety.

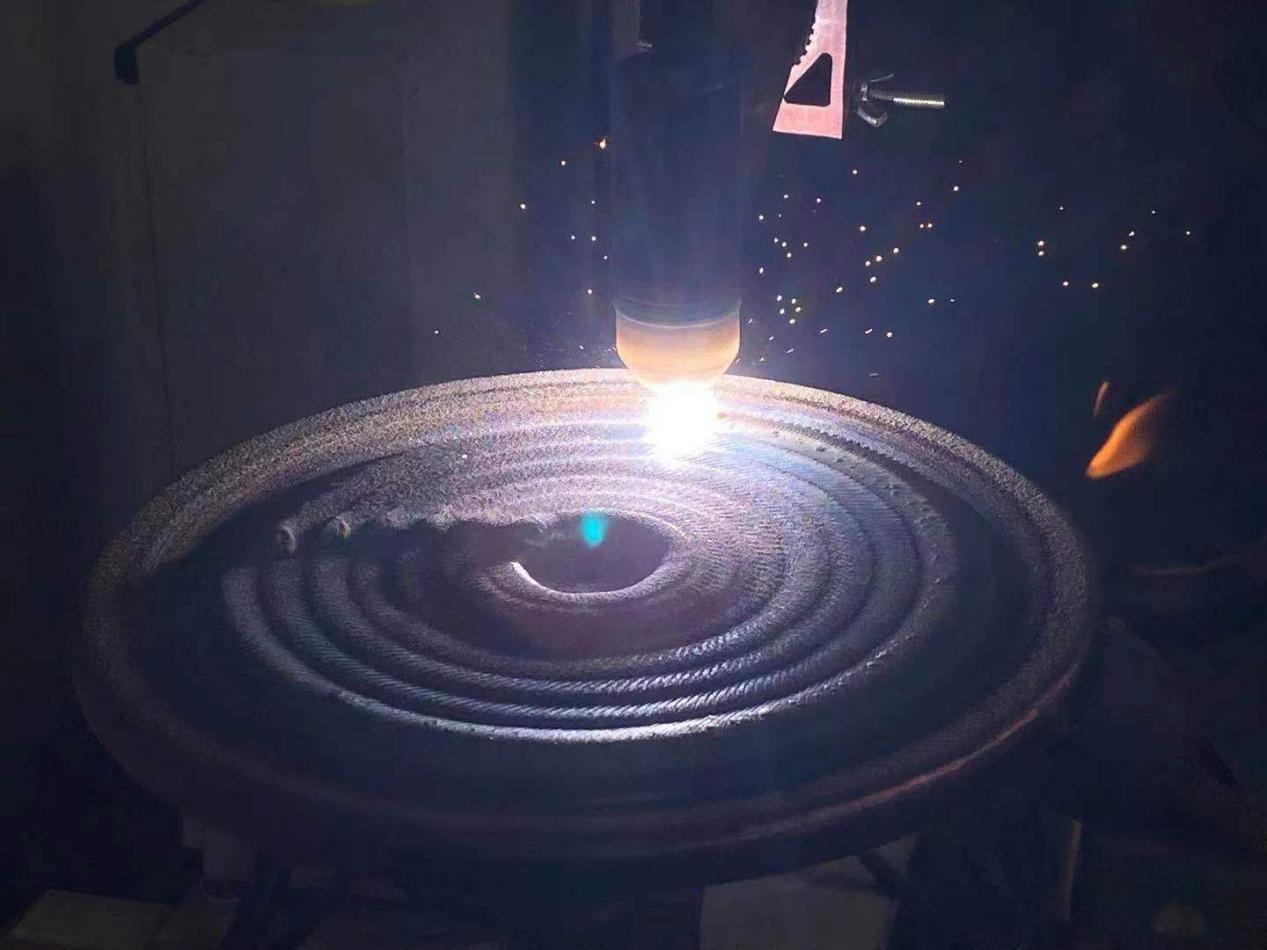

Plasma cladding, an advanced welding-based method, utilizes a high-energy plasma beam or arc to generate localized high-temperature and high-energy density heat sources on the valves' and gates' surfaces. This heat source melts the cladding material, which then fuses with the base material. Plasma cladding offers several key advantages over conventional welding methods:

Precision: Plasma cladding allows precise control and positioning of the cladding material, ensuring excellent bonding and consistency between the repair layer and the base material.

Minimal heat-affected zone: Plasma cladding minimizes heat input and reduces the heat-affected zone, minimizing the risk of distortion and metallurgical changes in the base material. This improves the quality of the repair layer.

Superior wear resistance: Plasma cladding's high melting temperature and rapid cooling rate result in fine-grained and dense repair layers, offering excellent wear resistance and corrosion resistance. This enables sustained performance under harsh operating conditions.

Process adaptability: Plasma cladding is suitable for a wide range of materials, including various valve and gate alloys, making it highly versatile for different applications.

In conclusion, plasma cladding is a valuable technique for repairing and protecting valves and gates. Its precision, minimal heat-affected zone, superior wear resistance, and process adaptability contribute to extending the service life and improving the performance of these critical components in industrial settings.

Post time: May-20-2023