How to surfacing Vlaves with PTA welding

There are some upsides of PTA welding due to adoption of plasma arc and alloy powder.

1 Fast cladding rate, high efficiency.

2 Controllable penetration depth, low dilution rate.

3 Flat surface, high density, the surfacing thickness 0.5-5mm.

4 High quality surfacing layer, stable working, without crack and pore

5 Wide range in application powder, such as cobalt-based, nickel-based, iron-based, copper-based etc, it is possible to make as your requirement.

6 It would be customized to configurate robot, universal or unique one as your work conditions.

Introduce of the PTA welding system for Valve

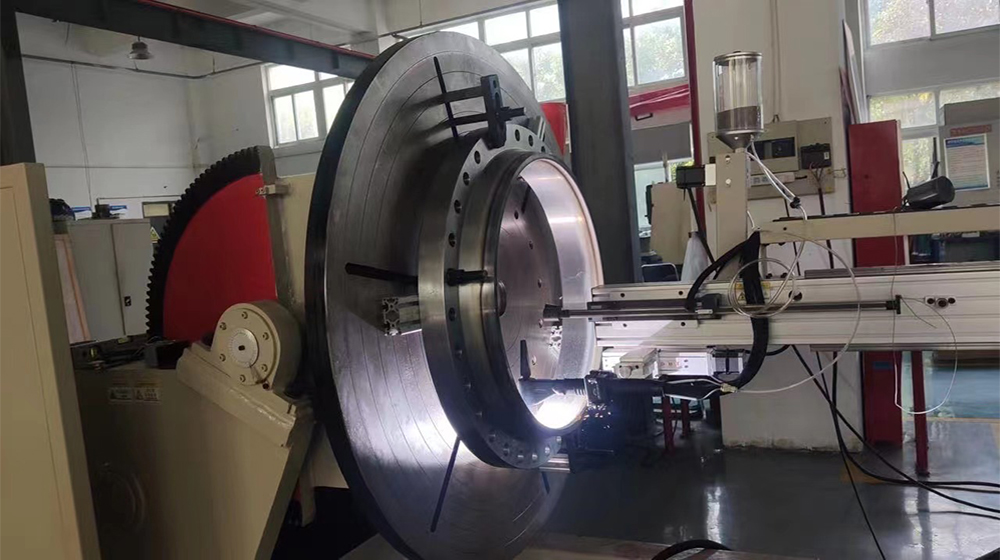

The set of PTA welding system with cross and positioner is especially for three eccentric valve we developed to improve the qaulity and efficiency.

Offline programming greatly reduces the difficulty of operating and improves the efficiency.

The set of PTA Welding system with the feeder of wire and powder, which would be switched at will.

The multi-station robot, which is the solution of high efficency and qaulity, realize the unmaned and automation.

Video

Post time: Nov-03-2022