Machina ad microplasma arcus soldandi accurata

Proprietates

1...Lamina et lamina per micro-plasmatis arcus soldadurae conglutinari possunt; energia arcus magna est, zona calore soldadurae affecta parva est, et deformatio soldadurae valde parva est;

2...Columna arcus magnam rigiditatem, effectum foraminis parvi, celeritatem soldadurae magnam et efficientiam productionis magnam habet, quae triplo ad sexies maior est quam soldadura argonica ordinaria;

3...Pauca sunt vitia suturarum, multae materiae suturabiles et alta qualitas suturarum;

4...Productio repetitiva excellens, electrodi in rostro contrahuntur, non facile polluuntur et usantur;

5...Arcus plasmatis magnam densitatem energiae, altam temperaturam columnae arcus, et validam facultatem penetrandi habet;

6...Columna arcuata gracilis est et penetrationem validam habet. Pars tenuis parietis directe per eam ferruminari potest et tempus praeparationis breviari. Chalybs crassitudine 0.3 ~ 1 mm per eam ferruminari et utrinque sine sulco formari potest (id est, uno latere ferruminando et utrinque formando). Deformatio sub tensione parva est.

Parametri hospitis Dml-v01a

| Machina ad arcum plasmatis micro-accuratam soldandam | |||

| Parametri technici principales et exempla | DML-V01A | ||

| Soldatura continua | Soldatura pulsatilis | Soldatura pulsus accurati | |

| Arcus currens (a) | 2.0-5.0 | ||

| Fluxus soldandi (a) | 0.1-10-40 | ||

| Currens fundamentalis (a) | 0.1-10-40 | ||

| Tempus ascensionis (s) | 0.0-5.0 | ||

| Tempus descensus (secunda) | 0.0-5.0 | ||

| Tempus soldadurae (MS) |

| 1-500 | 1-500 |

| Intervallum temporis (MS) |

| 10-500 |

|

| Praevia (vel praevia) traditione aerea | 1-10 | ||

| Mora temporis gasis (s) | 1-20 | ||

| Gas ionicum (L/min) | 0.25-2.5 | ||

| Gas protectivum (L / min) | 1-25 | ||

| Tensio ingressus (V) | AC 220V, 50Hz | ||

| Capacitas inputata nominalis (kVA) | 1.1 | ||

| Ratio durationis oneris (%) | LX% | ||

| Pondus (kg) | 28 | ||

| Dimensio externa fontis potentiae (mm) | 590*330*300 | ||

Commoda

1...Crassitudo laminae sudandae minor est quam ea quae sudandae est per arcum argonianum, plerumque 0.3-0.5 mm. Sine crispatione sudandi potest, et qualitas sudandae bona est.

2...In continua soldadura automatica tuborum, mutatio longitudinis arcus plasmatis parum afficit qualitatem soldadurae, quae differt a soldadura arcus argonii.

3...Cum fluxus sudandi parvus est (minus quam 3a), stabilitas arcus microplasmatis bona est, dum stabilitas arcus argonii mala est.

4...Propter concentrationem caloris, celeritas soldadurae arcus microplasmatis maior est quam soldadurae arcus argonii, et productivitas alta est.

5...Varia metalla, inter quae chalybs inoxidabilis, metalla non-ferrea et metalla refractaria, conglutinare potest.

Campi applicationis

1...Partes electronicae et electricae (thermocouple, motor, lamina chalybis siliconis, etc.)

2...Instrumenta, apparatus medicus (folles metallici, partes instrumentorum praecisionis, etc.)

3...Ferulatio metallorum specialium (velut titanium, nickel, molybdenum, aliaque metalla specialia etiam ferulationem efficientem adhibere potest)

4...Aeronautica et res spatiales (accessoria aeronautica, accessiones stationum spatialium, instrumenta transmissionis, sensoria gasorum, etc.)

Continua automatica arcu microplasmatico soldadura tuborum tenuissimorum similis est processui soldadurae arcus compressionis clausae. Manica insulationis inter matricem soldadurae et facem soldadurae inseritur ut firma insulatio inter facem soldadurae plasmaticae et partes metallicas praestetur. Simul, argon protector in parva camera inclusus est. Parametri processus soldadurae microplasmatici arcus pro tuborum tenuissimorum maiores sunt quam ii soldadurae arcus argon. Praeter currentem soldadurae, celeritatem soldadurae et fluxum gasis protectoris, etiam fluxus gasis operarii et compositionem gasis protectoris erunt. Hi parametri qualitatem soldadurae afficiunt. Experientia demonstrat principales parametros processus qui productivitatem tuborum tenuissimorum afficiunt esse currentem soldadurae, fluxus gasis operarii et diametrum foraminis fistulae.

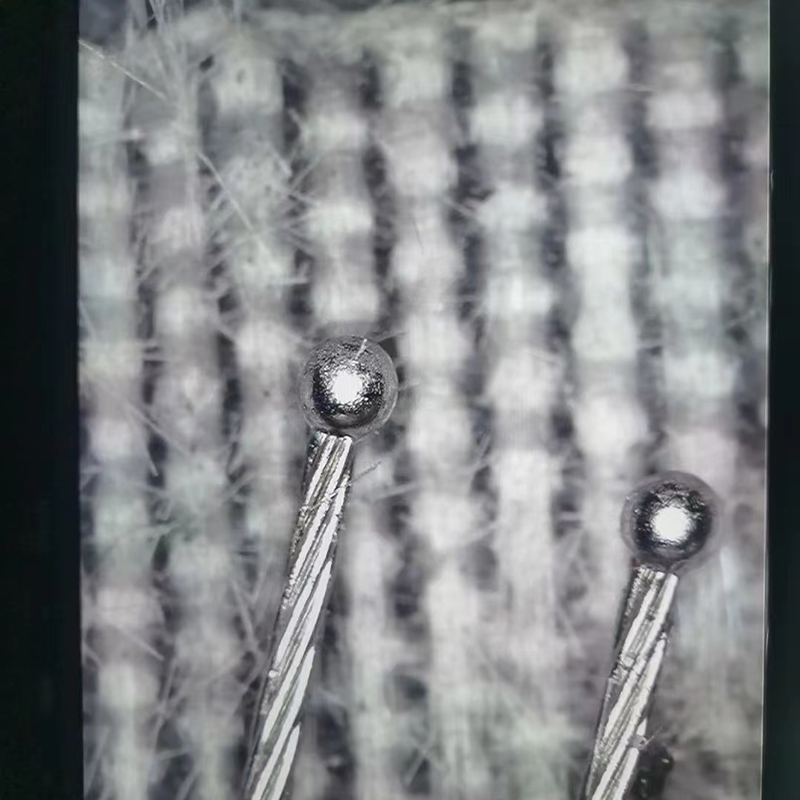

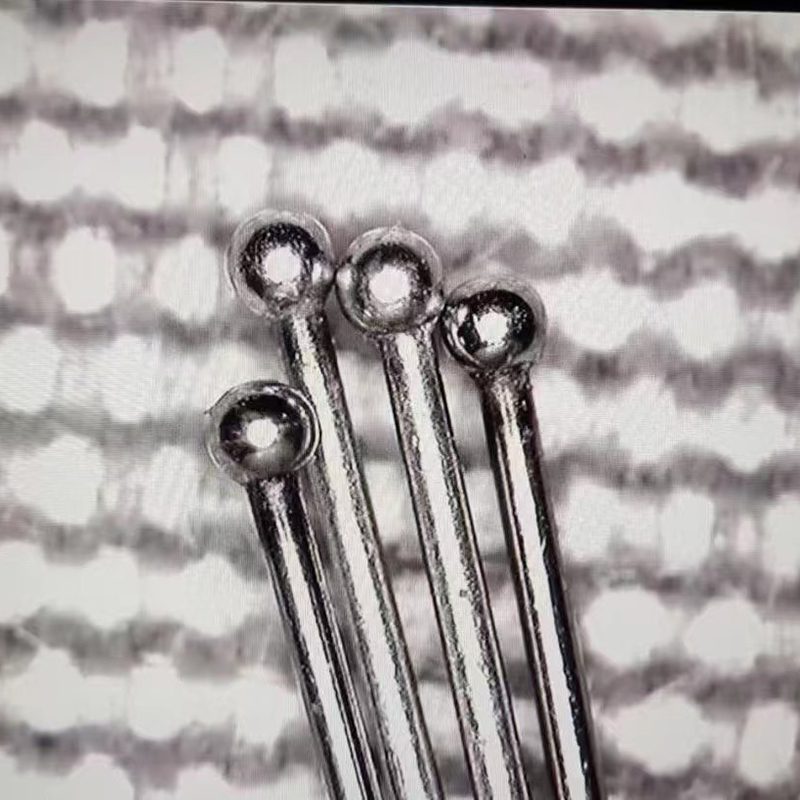

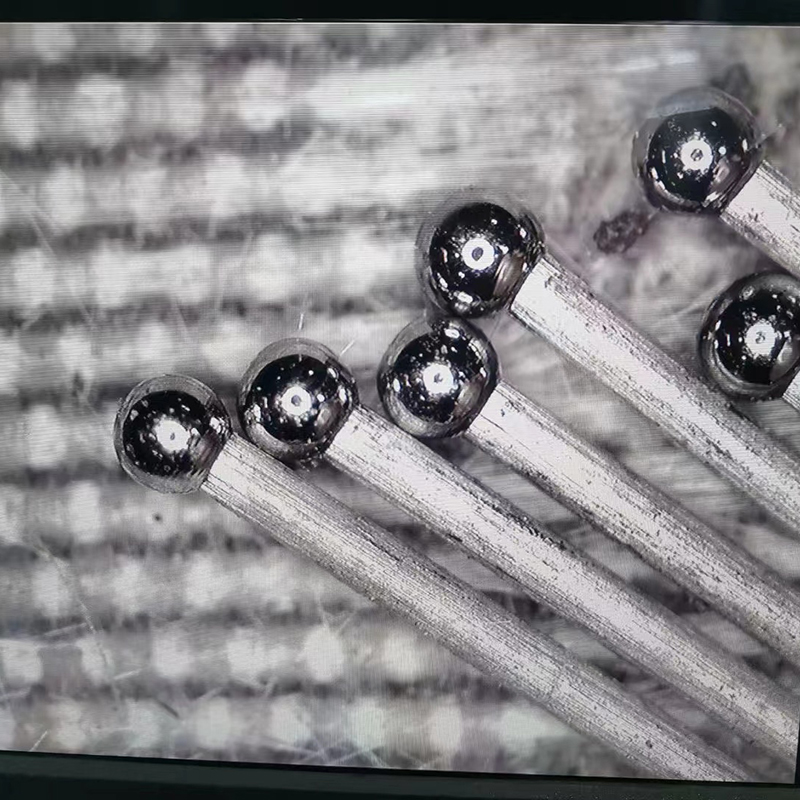

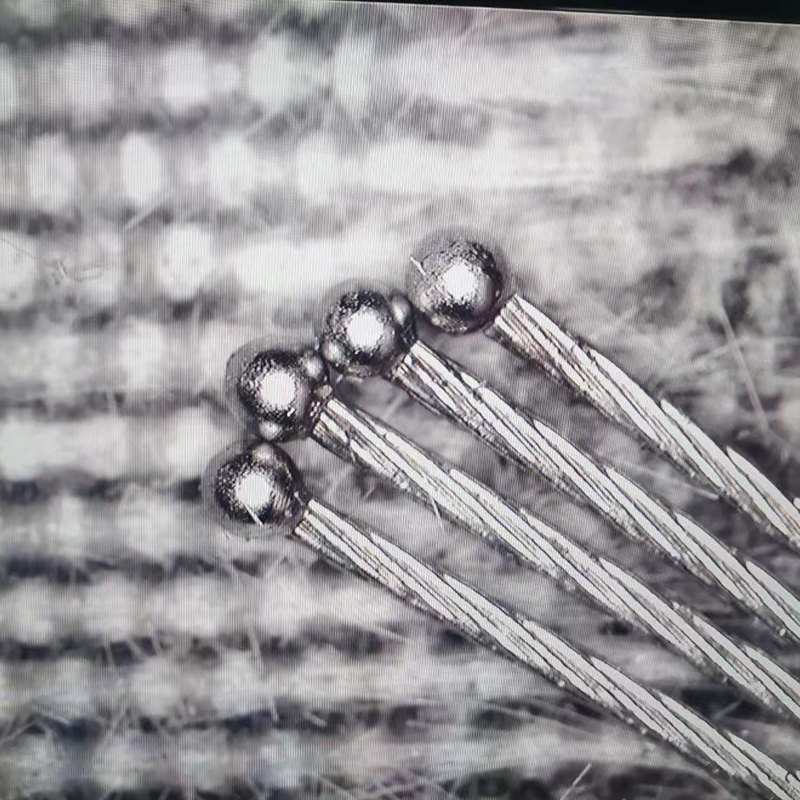

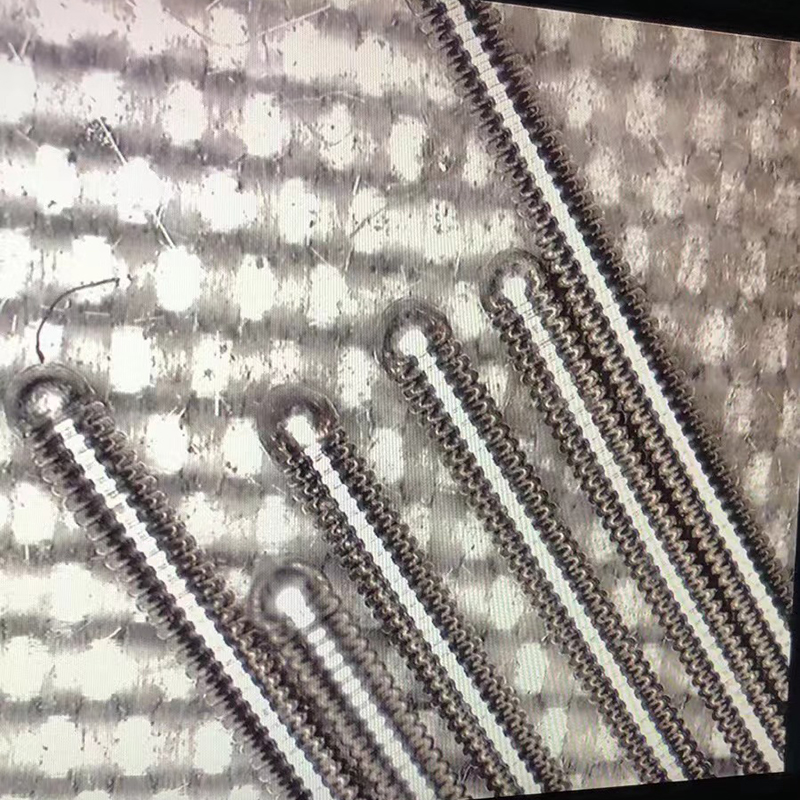

Imago ostentata