Fax Arcus Plasmatis Transferens (Fax PTA) est pars centralis machinae Arcus Plasmatis Transferens (PTA), quae arcum plasmatis generat et pulverem mixturae metallicae accurate ad aream suturae perfert. Structura et principium operationis eius a face suturae ordinaria differunt, cum praecisione et stabilitate maiori.

1. Partes structurales

TheFax soldandi PTApraecipue ex sequentibus partibus constat:

Cathodus (electrodus wolframiae): pars principalis ad arcum plasmatis generandum, plerumque ex materia wolframiae altae temperaturae et corrosioni resistens facta.

Anodus (fistula): arcum plasmatis dirigit et columnam arcus concentrat, plerumque ex cupro facta ad dissipationem caloris emendandam.

Systema pulveris alimentandi: Ad pulverem mixturae metallorum uniformiter in arcum plasmatis alimentandum adhibetur, ut liquefiat et in superficie materiae fabricandae deponatur.

Canalis gasis protectorii: Argon vel helium plerumque ut gas plasmatis et gas protectorium ad oxidationem in area soldadurae impediendam adhibetur.

Systema refrigerationis: Refrigeratio aquae adhibetur ad stabilitatem faces soldandi durante operatione altae temperaturae confirmandam.

2. Principium operandi

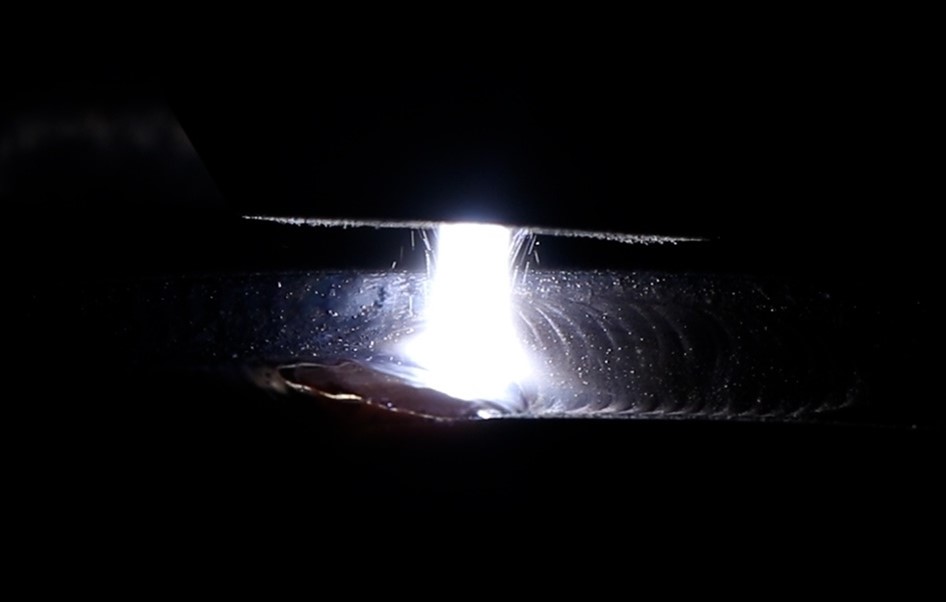

Gradus initiationis arcus: Impulsus altae frequentiae et altae tensionis arcum non-transferentem inter electrodum tungstenicum et fistulam generat (parva intensitas, initiatio arcus stabilis).

Formatio arcus plasmatis: gas plasmatis (velut argon) per fistulam, per ionizationem arcus altae temperaturae in plasmam altae energiae, et per fistulam ad superficiem materiae, formatio arcus transferentis (arcus principalis).

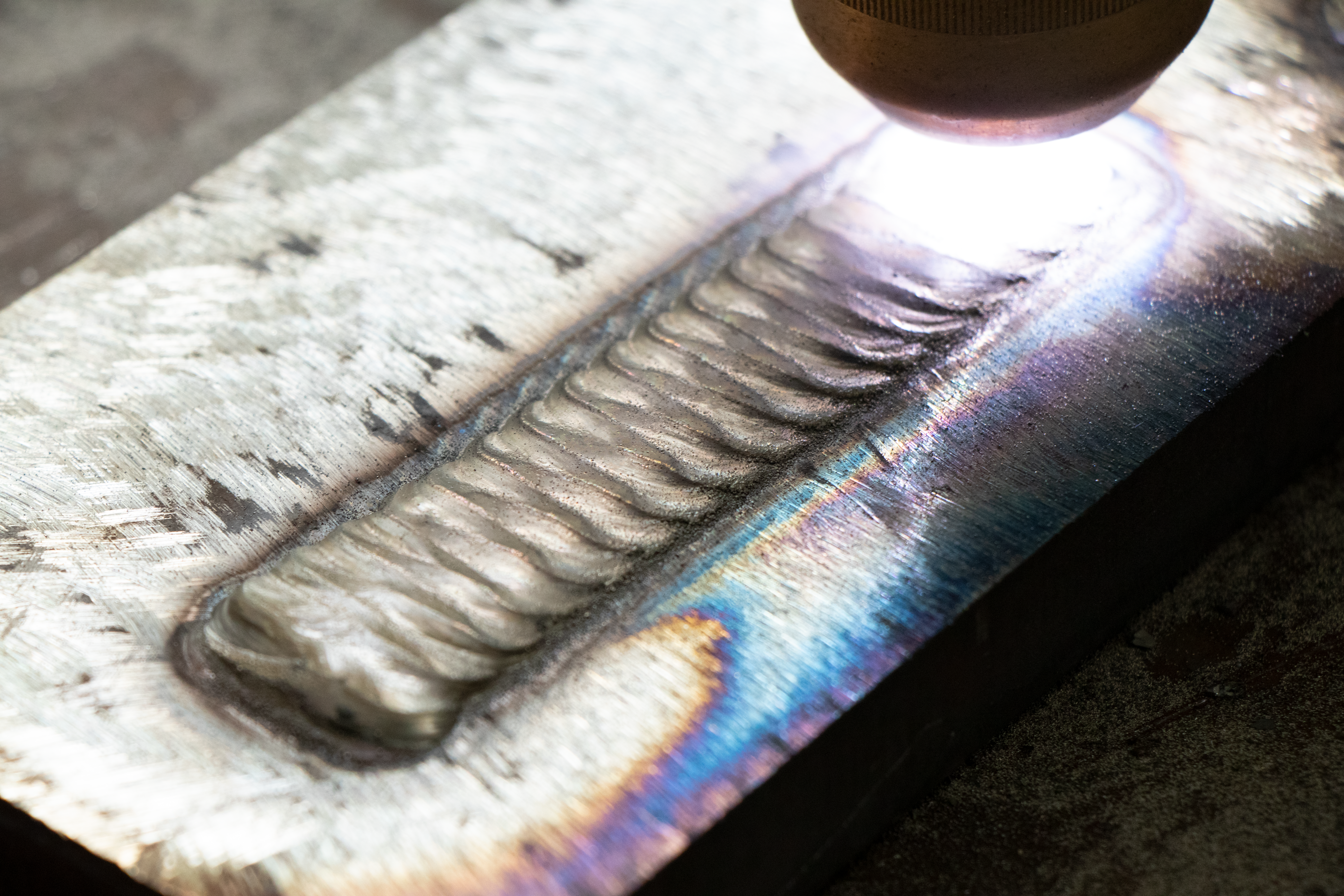

Alimentatio et liquefactio pulveris: pulvis mixturae metallorum uniformiter in aream arcus plasmatis per alimentatorem pulveris immittitur, statim liquefactus et in superficiem materiae dispersus est ad stratum densum formandum.

Ligatio metallurgica: Pulvis liquefactus cum materia basali metallurgicaliter ligatur ut stratum tegumenti altae firmitatis et attritioni resistens formetur.

3. Proprietates et commoda

Alta densitas energiae: columnae arcuatae longae et tenues, temperaturae altae (usque ad 20 000°C), accurata moderatio profunditatis liquefactionis et crassitudinis strati.

Parva zona calore affecta: Deformationem substrati et tensionem thermalem minuit, stabilitatem dimensionalem materiae fabricandae emendat.

Alta ratio usus materiae: ratio usus materiae pulveris plus quam 90% est, quod est oeconomicum.

Excellens qualitas obductionis: obductio densa, nulla porositas, magna vis nexus metallurgici, optima resistentia abrasioni et corrosioni.

4. Materiae et usus vulgo adhibiti

Materiae pulveris mixturae: pulveris mixturarum e cobalto, niccolo, ferro, carburo tungsteno et aliis pulveribus mixturis resistentibus detritioni et corrosioni.

Areae applicationis typicae:

Oleum et gas: Tegumenta resistentia attritioni et corrosioni pro valvis, terebris et corporibus antliarum.

Machinae ingeniariae: axes, cylindri, dentes, roboratio et reparatio superficiei formae.

Industria metallurgica: superficies reficiendae et reparandae cylindris, formarum, sedium valvularum aliarumque partium.

5. Cautiones usus

Praesidium electrodi tungsteni: oxidationem et deflagrationem prohibet, vitam electrodi prolongat.

Refrigeratio fistulae: bonum effectum refrigerationis aquae serva ne fistulae nimis calefiant.

Stabilitas pulveris alimentationis: uniformitatem pulveris alimentationis cura ut inaequalis crassitudo strati vel vitia scoriae vitentur.

Praesidium salutis: alta temperatura, operatio altae tensionis, necesse est instrueri larvis protectoriis, chirothecis, aliisque apparatibus salutis.

6. Comparatio cum aliis modis soldadurae

Cum soldadura arcus plasmatis (PAW): Soldatura PTA imprimis ad superficiem obducendam et firmandam adhibetur, dum PAW plerumque ad soldaduram penetrationis.

Comparatio cum Superficie Laser: Soldatura PTA vilior est et ad latiorem materiarum varietatem applicabilis; attamen superficies laser zonam calore affectam minorem et praecisionem maiorem habet.

Cum pulverizatione plasmatis: soldadura PTA est nexus metallurgicus, magnae firmitatis obductionis; pulverizatio plasmatis est nexus mechanicus, aptus ad tenui strato obductionis.

Tempus publicationis: XIX Februarii, MMXXXV