Soldatura Arcus Plasmatis Transferens, vulgo PTA vel PTAW appellata, est processus materiae obductae calore impulsus, in principio arcus plasmatis fundatus. Nucleus processus in usu arcus plasmatis altae temperaturae (usque ad 15 000°C) iacet ad materias metallicas pulverulentas liquefaciendas et metallurgicaliter iungendas superficiei substrati, ita formando obductiones functionales cum alta duritia, resistentia attritionis vel resistentia corrosionis. Soldatura Arcus Plasmatis Transferens (PTA) est evolutio naturalis processus GTAW et compensat defectum automationis soldaturae arcus tungsteni conventionalis (GTAW).tungstenum gas inertem protectummachinae ad soldandum TIG (vel TIG).

Principium Operandi Soldaturae Arcus Plasmatis Transferentis

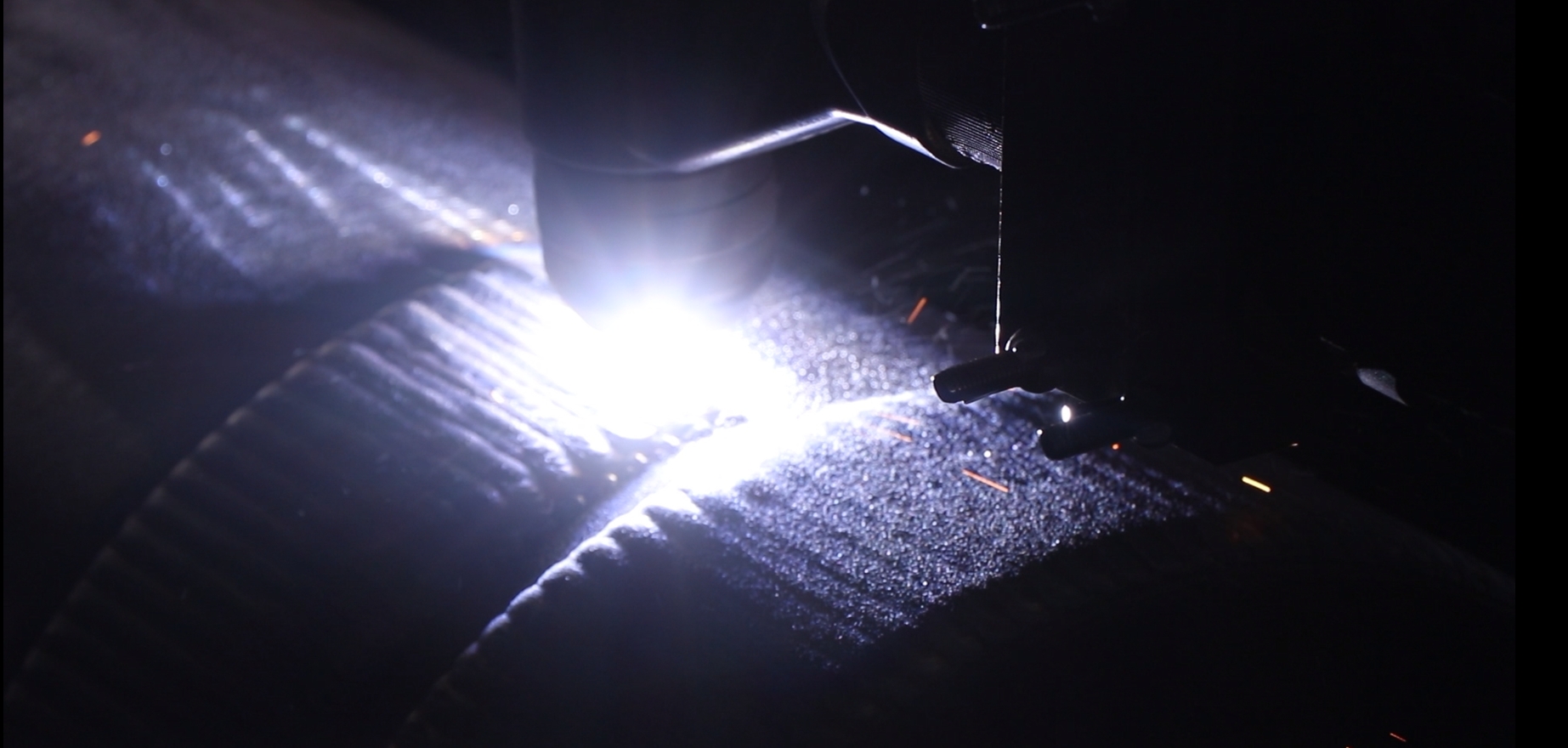

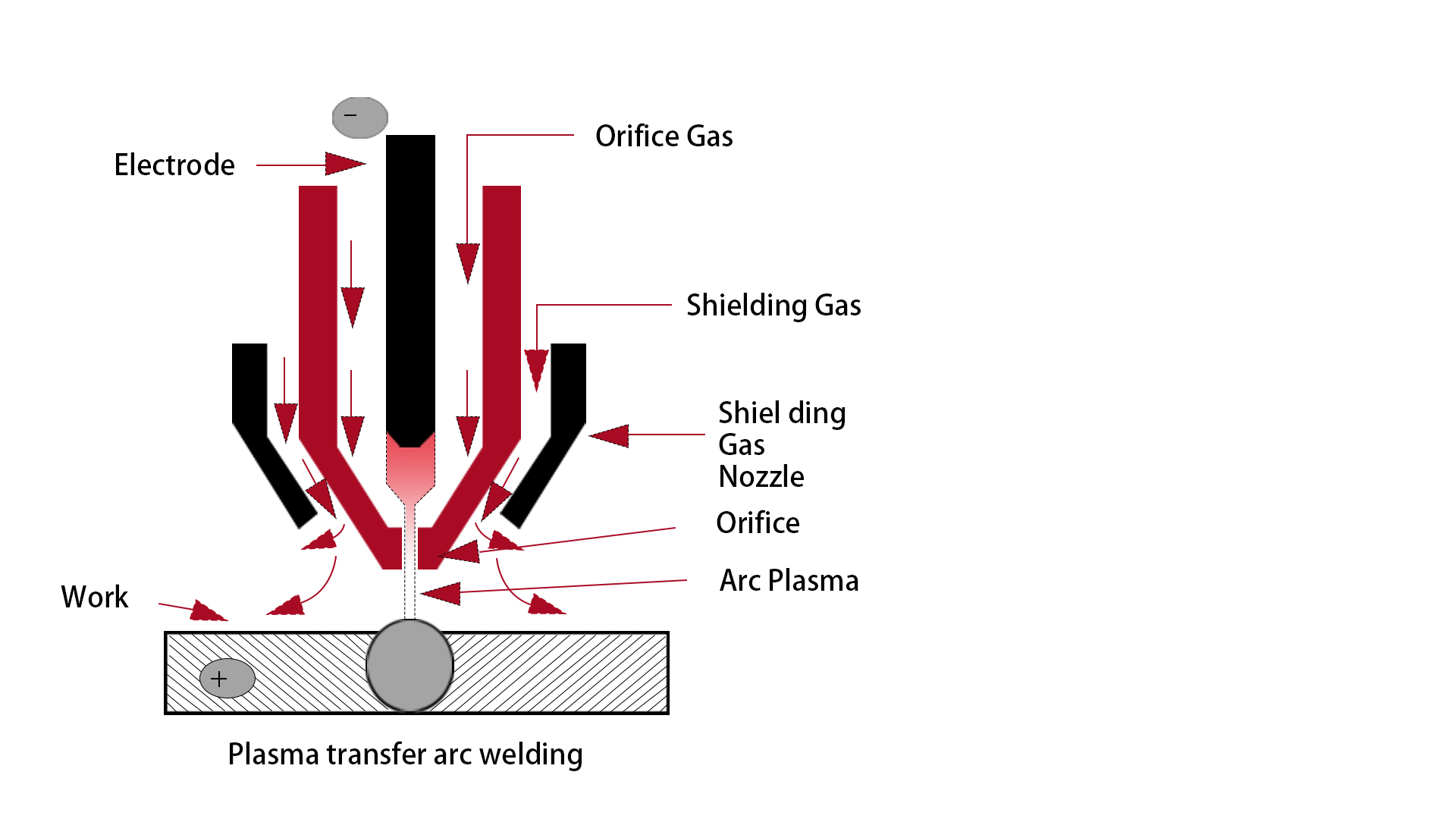

Sub actione fontis caloris altae temperaturae arcus plasmatis, materia tegumenti plasmatis (metallum vel pulvis mixturae metallicae) liquefacta et metallurgicaliter cum superficie substrati iungitur ut stratum firmans formet, et arcus ductus (arcus non transferens) formatur applicando parvum currentem electricum inter electrodum tungstenum et fistulam. Sub actione arcus altae temperaturae, gas iners (plerumque argon) ionizatur ut fluxum plasmatis altae temperaturae et altae densitatis formet. Essentialiter, plasma ad altas temperaturas, altas velocitates iactus et altas densitates energiae coercetur.

Quid interest inter PTAW et alias artes soldadurae?

Principium fundamentale omnium artium ferrariarum est materiam calefacere per fontem caloris, quo liquescat et suturam vel stratum obductum formetur. Sed Ferraria Arcus Transferens Plasmae (GTAW) proxima est principio methodo GTAW, quia ambae electrodos tungstenos non consumibiles utuntur. Ferraria PTA reformata est ut arcum gubernatorem a face avertat, ut per fistulam aeneam subtiliter perforatam suffocetur, quod densitatem energiae maiorem efficit. Ferraria PTA magis in roborando et reparando superficiem intendit quam methodi ferrariae conventionales, dum aliae methodi ferrariae (e.g., TIG, MIG, ferraria laserica) magis in iuncturis et ferraria partium structuralium versantur. Ad comparationem accuratiorem videndam,clic.

Materiae communes pro tegumento soldadurae PTA

•Mixturae ferreae

•Mixtiones niccoli fundatae

Inconel 625

Inconel 718

plus

•Mixturae cobalto fundatae

Stellita 6

Stellita XII

plus

•Mixtiones chromii fundatae

CR20

CR25

plus

•Carburum tungstenum

Solutiones Superficierum Soldaturae PTA

Causae principales eligendiSolutiones superpositionis suturae PTAOb praecisionem magnam, qualitatem tegumentorum excellentem, usum materiae magnum (>90%), facultates automationis, et adaptabilitatem multi-materiae. Comparata cum SMAW, GMAW, TIG, aliisque technologis ferrariae, ferraria PTA excellit in condicionibus tegumentorum resistentiae detritionis et corrosionis, commoda efficacitatis et sumptus coniungens.

Areae Applicationis

•Petrochemica

•Metallurgia

•Aerospatiale

•Autocinetica

•Energia

•Medica, et cetera.

Eligendo rectam PTA suturam tegumenti

Shanghai Duomu Industry Co., Ltd. Varias machinas et solutiones ad soldaduram PTA et superimpositionem introducimus. Societas ordinationem independentem investigationis et progressionis habet, ut utilitatem producti, stabilitatem, et technologiam continuae renovationis curet. Producta praecipua, quae in technologia moderationis DSP provecta (celeritate alta, praecisione alta, facultate anti-interceptionis technologiae processus signorum digitalium) fundantur, et series soldadurae arcus plasmatis translationis efficaciae superioris gradum provectum industriae attigit. Interesse habes in hac re.Instrumenta ad soldandum PTAVisne consilium peritorum de optimis solutionibus industriae ad soldaduram et obductionem PTA pertinentibus?Contacta nos!

Tempus publicationis: XVI Ianuarii MMXXXV