Dolores carbonarii sunt machinae carbonariae et machinae perforationis cuniculorum in fodinis adhibitae. Commoda et incommoda qualitatis dolarum carbonariarum directe efficientiam machinae carbonariae et sumptus productionis societatum afficiunt. Cum crescente postulatione energiae, praesertim carbonis, ad efficientiam fodinarum augendam, potentia machinae carbonariae pergit crescere, qualitas dolarum carbonariarum magis ac magis excellit. Cum materiae dolarum carbonariarum requiruntur ut magnae sint firmitas, duritia, resistentia abrasioni, alta resistentia flexionis, et corrosionis, ne usus dolarum carbonariarum in processu fracturae, flexionis, deformationis, et detritionis praematurae fiat.

Classificatio generalis plectrorum fodinarum est: dentes carbonarii, dentes fossores, dentes fossores rotatorii, et cetera.

Materia communis ad fodinas eligendas

Materia communis ad fodinas eligendas

In praesenti, series materiarum apicularum fodinarum, tam domesticae quam externae, plerumque adhibentur, praesertim systemata Cr-Mo, systemata Mn-B, systemata Cr-Ni-Mo, systemata Cr-Mn-Si, systemata Si-Mn-Mo, et cetera. Ex methodo productionis, praecipue materiae apicularum fodinarum fusae et materiae apicularum fodinarum cudendae derivantur.

Processus productionis aculeorum fodinarum in tres typos dividi potest.

(1) Corpus plectri elaboratur et formatur, caput e carburo braseato, in fornace salina calefactum, isotherme sale nitrato refrigeratum et temperatum est.

(2) Corpus aculei fodinae tractans et fingens, fornax salis calefaciens, nitrati salis isotherme restinguens, purgans, caput carburi brasans, et temperans.

(3) Technologia integrationis brasiendi et curationis caloris.

(1) Carburum superficiale. Stratum superficiale detritioni resistens aculeorum fodinarum est usus materiae superficialis magnae duritiae et resistentiae detritioni. In superficie capitis corporis dentium aculeorum fodinarum, unum vel plura strata materiae superficialis adhibentur, cingulum protectivum formantes. Stratum magnam resistentiam abrasioni et bonam resistentiam corrosioni habet, ita ut materia capitis dentis corporis braccarum aculeorum fodinarum non directe cum saxo carbonis effoditur in contactu. Hoc fit ut frictio et ictus capitis dentis corporis materiae et suturae carbonis aliaque munera minuantur, detritionem et lacerationem tardantes, et vitam utilem aculeorum extendentes. Superficies commoda habet instrumentorum simplicitatis, sumptus humilis, operationis flexibilitatis, et aptationis ad plenam varietatem superficierum.

(2) Superficiem aspergendo thermali. Alia methodus tractationis superficialis aculeorum fodinarum est usus technologiae aspersionis thermalis ad resistentiam attritionis et vitam utilem capitis aculei fodinae augendam. Exempli gratia, caput materiae aculei fodinae alta temperatura aspergens strato ceramicae metallicae, duritiam capitis auget (HRC ≥ 60), alta duritie, bona resistentia attritionis, vita utilis aculei fodinae plus quam 50% augeri potest!

(3) Methodi metallurgiae superficialis. Technologia metallurgiae superficialis arcum plasmatis ut fontem caloris adhibet; superficies materiae substrati stratum densum uniformem efficit, cum valido speciali obductione protectiva coniunctum, ut nexus metallurgicus obductionis et substrati metallici efficiatur. Obductio plasmatis est processus solidificationis celeris non-aequilibrii. Cum roboratione solutionis solidae supersaturatae, roboratione dispersionis et roboratione praecipitationis aliisque effectibus roborantibus, stratum metallurgicum obtentum resistentiam abrasioni, corrosionis, et oxidationis temperaturae altae altissimam habet. Efficacia.

(4) Tractatio chemica caloris. Tractatio chemica est carburizatio superficiei aculeorum fodinarum, infiltratio bori, infiltratio chromii, aliaeque tractationes caloris chemicae, ita ut superficies aculeorum fodinarum composita maioris duritiei formet, quae resistentiam superficialem contra attritionem augent. Per borizationem 40CrNiMo et tractationem chromii, superficies composita bori et chromii formatur, duritia superficialis et resistentia contra attritionem augetur, ita ut vita utilis aculeorum fodinarum augeatur.

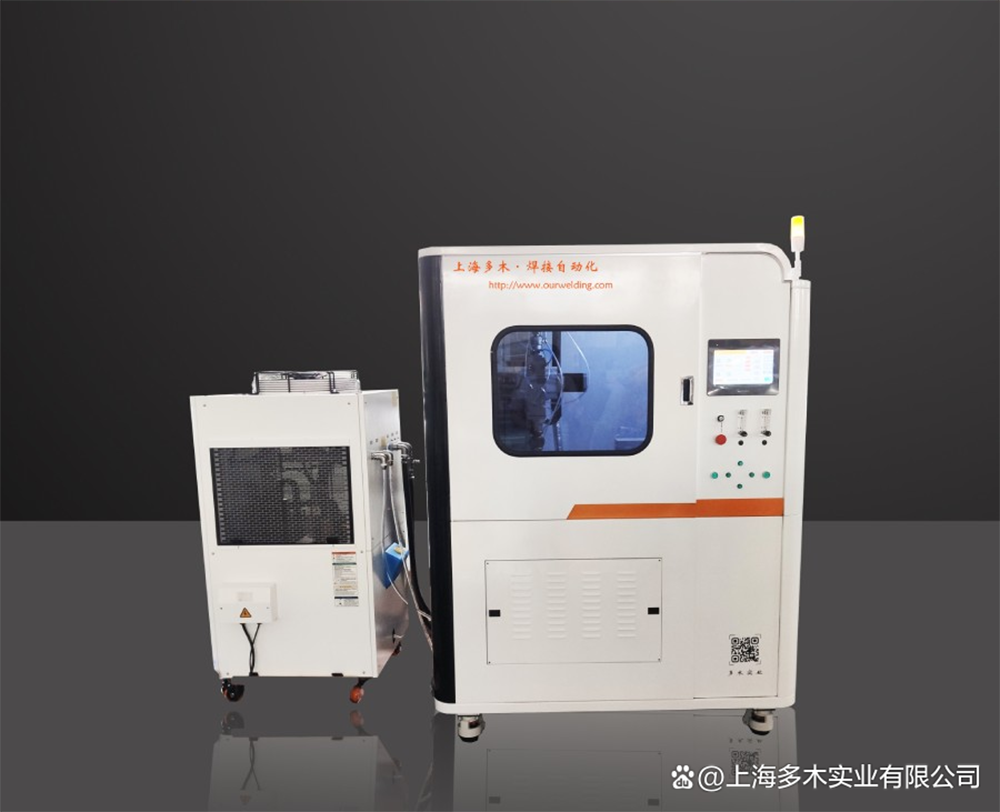

Processus obductionis lasericae pro aculeis metallicis

Laser ut fons caloris ad pulverem in superficie materiae liquefaciendum adhibetur, nexus metallurgicus magna vi nexus et dilutionis parva ratione efficitur. Obductio laserica nova technologia modificationis superficiei est. Principium est ut radius lasericus altae densitatis cum compositione et proprietatibus mixturae metallorum et superficiei substrati diversa celeriter liquefiat. Formatio superficiei substrati et substrati compositionem et proprietates strati mixturae metallorum omnino differentes habet, comparata cum superficiebus, aspersionibus, incrustationibus, aliisque modis traditis quae dilutionem, densitatem textus, obductiones et nexus substrati parvam habent, apta ad fusionem plurium materiarum, magnitudinem particularum et contentum magnas mutationes in proprietatibus materiae subeunt.

Aculei laserici ad obductionem metallicam fodinarum proprietates habent resistentiae attritionis, longae vitae, difficile frangendi, et nullae scintillae. Non solum sumptus productionis carbonis minuunt, intensitatem laboris operariorum minuunt, sed etiam bonam solutionem praebent problemati diuturno quod tuta productio carbonis periclitatur propter usum aculeorum in processu scintillarum generandarum; applicatio materiarum lasericarum ad obductionem metallicam fodinarum ut indices effectuum aculeorum et forma strati obductionis cum versatilitate et facilitate controllationis efficiant; applicatio materiarum lasericarum ad obductionem metallicam et processus obductionis solutionem completam praebet problematibus processus brasitionis in capite dentis causatis propter mollitiem recoctionis.

Tempus publicationis: XI Septembris, MMXXIII