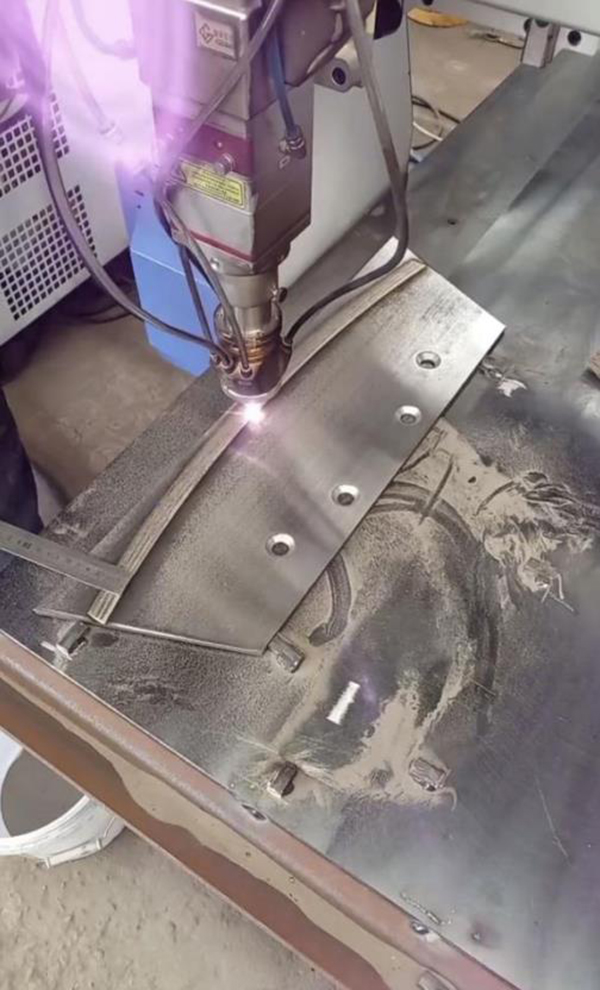

Obductio laserica pontis plani

Commoda obductionis lasericae

1. Celeris refrigerationis celeritas (usque ad 106℃/s), ad processum solidificationis celeris pertinet, facile ad ordinationem crystalli subtilem obtinendam vel statum aequilibrii producendum, novam phasim non obtineri potest, ut phasis instabilis, status amorphus;

2. Stratum obducens et substratum sunt fortis combinatio metallurgica vel combinatio diffusionis interfacialis, humilis dilutionis ratio, fortis controllabilitas, secundum necessitates ad moderandam longitudinem focalem soldadurae, moderandam profunditatem fusionis soldadurae, et deinde moderandam rationem dilutionis soldadurae;

3. Partes reparationis roboris obductionis lasericae parvum impulsum thermalem, parvam deformationem, solam dissolutionem superficialem in processu processus habent, et area impulsus thermalis basis parva est, plerumque inter 0.1-0.5 mm;

4. Matrix et materia tegumenti metallurgice coniuncta sunt, et vis ligationis comparabilis est materiae basi;

5. Crassitudo et duritia strati tegumenti magna est, et stratum tegumenti densum est, sine poris, scoriis, fissuris aliisque defectibus, et duritia strati tegumenti 18-60HRC attingere potest;

6. Paene nullae sunt restrictiones in delectu pulveris, liquefaciens mixturam alto liquefactionis in superficie metalli basso liquefactionis;

7. Laser aptus est ad transmissionem longam distantiam, et partes magnae in situ reparari possunt;

8. Obductio laserica proprietates habet soldadurae sine contactu, nonnullis sulci, obductionis foraminis profundi;

9. Tegumentum manuale flexibile est, et partes formae complexae leniter reparari possunt, sine molestia programmandi vel automationis;

Imago ostentata