DLG-NC401 Machina automatica cochlearum ad soldandum

Processus laboris

(1) Arcus generatio

Duo genera instrumentorum arcus generantium intra apparatum sunt, quae arcum non transferentem et arcum transferentem respective praebent. Electrodi negativi duarum fontium potentiae paralleliter connexi sunt et per filum cum electrodo tungsteno (electrodo negativo) tormenti conglutinati connectuntur. Polus positivus fontis potentiae arcus non transferentis per filum cum fistula tormenti conglutinati connectitur, et polus positivus fontis potentiae arcus transferentis per filum cum materia laboris connectitur. Aqua refrigerans per filum aqua refrigeratum ad tormentum conglutinatum ducitur ut fistula et electrodum refrigerentur. Argon per valvulam solenoidem et rotametrum facem conglutinatam intrat. Postquam potentia accensa est, arcus non transferens scintilla altae frequentiae accenditur. Deinde arcus transferens canali conductivo inter electrodum tungstenum et materiam laboris, flamma arcus non transferentis effecto, accenditur. Postquam arcus transferens accenditur, arcus non transferens retineri vel abscindi potest. Arcum transferentem praecipue adhibet ad lacum liquefactum in superficie materiae laboris producendum.

(2) Emissio pulveris ad soldericum

Pulvis mixturae metallorum a distributore pulveris secundum postulationem continenter suppeditatur, et gase pulveris alimentante (plerumque argon) in tormentum ferrurae immittitur et in arcum insufflatur. Pulvis mixturae metallorum in columna arcus prae calefactus, in statu liquefacto vel semi-liquefacto, et in piscinam liquefactam materiae infunditur, ubi plene liquefactus est, et gas ac scoria emittuntur.

(3) Adaptatio parametrorum

Arcus transferens et arcus non transferens, quantitatem pulveris alimentatam, aliosque parametros processus adaptando, calor ad rem laborandam et pulverem mixturae liquefactae translatus regi potest. Motu relativo sclopeti ferrariae et rei laborandae, lacus mixturae paulatim solidificatur et stratum depositi mixturae requisitum in re laboranda obtinetur.

Characteres

Collata cum aliis methodis superficierum faciendarum, superficies plasmatica multa commoda habet, quia arcum plasmaticum ut fontem caloris et pulverem mixturae metallicae ut metallum implens utitur.

(1) Celeritas obductionis tegendae magna et productivitas magna.

(2) Penetratio est regibilis et dilutionis ratio humilis.

(3) Superficies plana et levis est, densitate magna, et superficies 0.5-5mm uno tempore perfici potest.

(4) Stratum superficiale stabile per longum tempus continuo obtineri potest, et superficies superficialis nullas difficultates qualitatis, ut porositatem et trachomam, habet.

(5) Pulvis mixturae facile paratur et in ampla varietate materiarum adhiberi potest. Materiae ad suturam pulveris cobalto, niccolo, ferro et cupro fundatae eligi possunt, et formula secundum condiciones laboris directe formari potest.

(6) Machinis specialibus, robotis, etc., pro necessitate instructum esse potest, quo facile automationem efficiatur et laboris intensitatem minuatur.

(7) Alta est ratio usus pulveris, et ratio usus plus quam 75% attingere potest.

Conspectus

Cochlea, ut pars principalis machinarum plasticarum, eius vita valde limitata est, pars substitutiva fragilis est. In usu industriali, ad efficientiam productionis augendam, tempus inoperabile instrumentorum minuendum, et cetera. Ergo, curatio superficiei roborandae (resistentia attritionis, resistentia altae temperaturae, et resistentia corrosionis) cochleae per superficiem plasmaticam efficitur, ut requisitis condicionum laboris satisfaciat.

Materia

Plus quam 90% fabricatorum materiarum plasticarum corporum cochlearum machinarum 38CrMoAl (chalybs nitridans provectus) utuntur, et nonnulli 42CrMo.

38CrMoAl est genus chalybis nitridandi provecti, quod praecipue adhibetur ad partes nitridandas cum magna resistentia detritionis, magna vi lassitudinis et accurata magnitudine post tractationem caloris, vel varias partes nitridandas cum parvo onere impetus sed magna resistentia detritionis, ut virga perforatoria, fusus trituratoris, fusus torni automatici, vermis, cochlea praecisionis, rota dentata praecisionis, valvula altae pressionis, caulis, mensura, forma, cylindrus, forma imitationis, cylindrus, etc. Virga pistonis compressoris, regulatoris, manica rotans et manica fixa turbinae vaporis, variae partes resistentes detritioni extrusoris gummi et plastici, etc.

Technologia superficiei

1.Materia superficialis

Pulvis mixturae niccoli fundatus (generaliter niccolum 60) et pulvis carburi niccoli fundatus (addendo proportionem correspondentem pulveris carburi cum niccolo 60 ut pulvere basi secundum postulationem producti).

2.Requisita pulveris

(1) Secundum proprietates requisitas productorum (resistentia attritionis, resistentia corrosionis, resistentia altae temperaturae), pulverem mixturae idoneum elige.

(2) Coefficiens expansionis thermalis pulveris mixturae metallicae prope coefficientem materiae matricis esse debet. Ne coefficiens expansionis thermalis nimis magnus sit, quo maior contractio efficiatur, quae fissuras producti efficit. Fissurae etiam per praecalefactionem et conservationem caloris regi possunt.

(3) Pulvis mixturae est pulvis sponte liquefaciens cum bona fluiditate (pulvis sphaericus optimus est) et magnitudine particularum uniformi. Stabilitas superficiei augeri potest.

(4) Celeritas pulveris alimentationis uniformis est, et celeritas plerumque 10-30g/min est. Optima magnitudinis particularum spatium est 150-300 mo. Fluxus gasis spatium 2.0-2.5l/min.

3.Requisita cochlearum

Superficies superficialis cochleam ex pulvere mixturae superficialis requirit, et praemissa est curare ut superficies cochlearum libera sit ab oleo, rubigine et vitiis manifestis.

4.Requisita instrumentorum

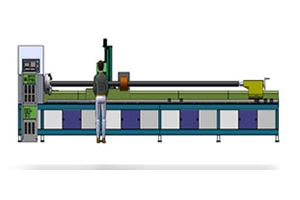

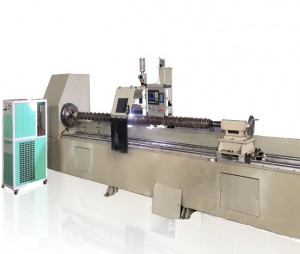

Apparatus ex machina ad soldandum pulverem plasmaticum et apparatu ad soldandum automatico constat.

(1) Machina ad suturam pulveris plasmatis cum acervo

Tres genera machinarum ad suturam pulveris plasmatis a societate nostra producta sunt: dml-v02bd (100a), dml-v03ad (160A) et dml-v03bd (300A). Potentia variat a magna ad parvam, quae secundum condiciones laboris actuales eligi potest. Fons potentiae motoris principalis designum valde integratum adhibet, cum efficacia superiore et volumine parvo. Cisterna aquae refrigeratoriae compressore magnae potentiae instructa est, qui aquam refrigeratoriam temperatura constante diu servare et postulationem laboris continuam diu praestare potest.