Quomodo superficiem obturamenti valvulae duram reddere cum soldadura PTA

In industria valvarum, semper sunt problemata communia solvenda. Exempli gratia, consilium absurdum, fabricatio neglegens, electio materiae vitiosa, compositio inordinata, cura incuriosa, et cetera. Haec omnia ex laesione superficiei obturantis valvae oriuntur.

Praeterea, si sub condicionibus operationis normalis dissolutio est, vix vitatur corrosio et ablutio a medio ad superficiem sigilli.

Valvam portae non secundum requisita oneris accipit. Aut modus claudendi nimis celeris est aut nimis strictus. Tractatio caloris impropria, durities superficiei obturantis nimis alta aut nimis humilis, haec omnia erosioni resistere non possunt.

Praeterea, laesio mechanica est causa principalis. In initio ictus, mensurare et percutere propositum est; propter vim altae temperaturae et pressionis, moleculae inter se infiltrantur et exosmosis fiunt, quod phaenomenon adhaesionis efficit.

Methodo reproductionis ad valvulam ferream reparandam semper utimur. Materiae superficiales valvulae sunt mixturae cobalti, niccoli, ferri, et cupri, quae in electrodos, fila ad soldandum (incluso filo nucleato), fluxum (incluso fluxo mixturae transitionalis), et pulverem mixturae, etc., fiunt, utens soldadura arcus manualis, soldadura flammae oxyacetylenicae, soldadura argonii tungsteni, et soldadura automatica arcus submersi. Hic processum obductionis soldadurae PTA introducimus.

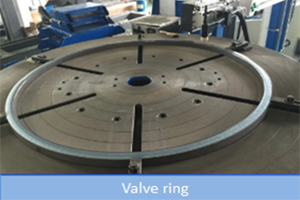

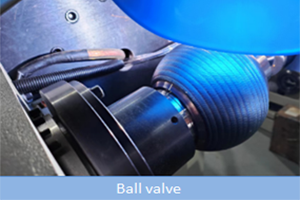

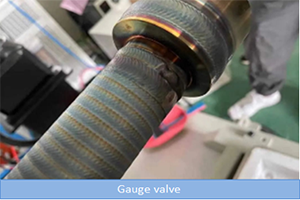

Casus applicationis in valva ut sequitur,

Video

Tempus publicationis: II Non. Nov. MMXXII