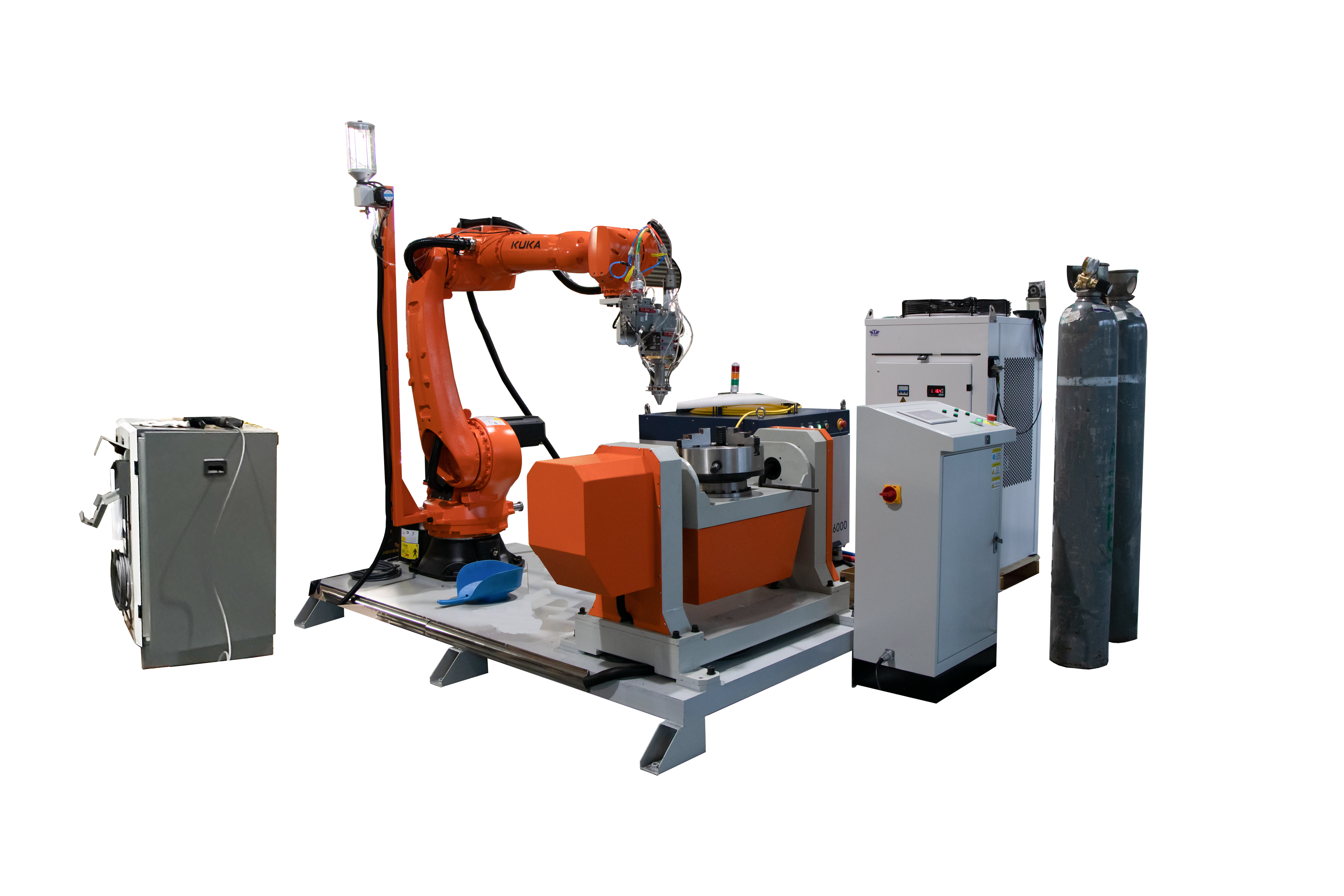

Automatisierte Laserauftragschweiß- und -beschichtungsanlagenEs handelt sich um eine industrielle Anlage, die mit einem Hochenergie-Laserstrahl ein Beschichtungsmaterial, beispielsweise ein Legierungspulver oder -draht, auf die Oberfläche eines Metallsubstrats aufschmilzt und aufträgt. Diese Technologie verbessert die Oberflächeneigenschaften des Werkstücks, wie Verschleiß-, Korrosions- und Hochtemperaturbeständigkeit, senkt gleichzeitig die Kosten und verlängert die Lebensdauer der Bauteile. Das automatisierte System gewährleistet hohe Präzision und effizienten Betrieb und eignet sich für die Serienfertigung und Reparatur komplexer Teile.

I. Funktionsprinzip

1. Fokussierung des Laserstrahls:Der hochenergetische Laserstrahl wird durch das optische System auf die Oberfläche des Werkstücks fokussiert.

2. Materialschmelze:Das verschmolzene Material (Pulver oder Draht) wird über das Pulverförder- oder Drahtfördersystem in das Laserschmelzbad eingespeist.

3. Poolbildung:Der Laser schmilzt die Oberfläche des Substrats und bildet ein Schmelzbad, in dem das Beschichtungsmaterial mit dem Substrat verschmolzen wird.

4. Schnelle Abkühlung:Die Schmelzschicht wird schnell abgekühlt und verfestigt sich, wodurch eine metallurgisch mit dem Grundmaterial verbundene Schmelzschicht entsteht.

II. Zusammensetzung der Ausrüstung

1. Lasersystem

- Lasertyp:Faserlaser, CO₂-Laser, HalbleiterlaserDie

- Leistungsbereich: normalerweise zwischen500 WUnd10 kWabhängig von den Prozessanforderungen.

2. Pulver-/Drahtzuführungssystem

-Pulverdosierer: Präzise Steuerung der Zufuhr des Verkleidungsmaterials, um die Gleichmäßigkeit der Verkleidungsschicht zu gewährleisten.

- Drahtvorschubgerät: Geeignet für dickere Deckschichten.

3. CNC-Bewegungssystem

- 3-Achsen-/5-Achsen-CNC-Plattform: Steuerung der Bewegung des Laserkopfes oder des Werkstücks zur Realisierung der Beschichtung komplexer Formen.

- Robotersystem: geeignet für die Mehrwinkelbearbeitung komplexer Werkstücke.

4. Kühlsysteme

- Laserkühlung: Üblicherweise wird ein Wasserkühlsystem eingesetzt, um einen stabilen Betrieb des Lasers zu gewährleisten.

- Werkstückkühlung: um Verformungen oder Leistungseinbußen durch Überhitzung zu verhindern.

5. Automatisches Steuerungssystem

- Softwaresystem:CAD/NOCKENProgrammierung zur Unterstützung der automatisierten Produktion.

- Überwachungssystem: Echtzeitüberwachung von Temperatur, Laserleistung und Schmelzbadzustand während des Schmelzprozesses.

III. Prozessmerkmale und Vorteile

1. Hohe Präzision und Effizienz

Die Laserstrahlsteuerung ist präzise, und die Dicke der Deckschicht kann im Bereich von0,1–5 mmDie

- Das automatisierte Steuerungssystem gewährleistet Konsistenz und Effizienz im Verarbeitungsprozess.

2. Hohe Materialverträglichkeit

- Unterstützung einer Vielzahl von Verkleidungsmaterialien:eisenbasiert, Nickelbasiert, Kobaltbasierte LegierungenUndVerbundwerkstoffeDie

- Es ermöglicht die Realisierung von Verbundverkleidungen aus verschiedenen Materialien und verbessert die Leistung.

3. Kleine Wärmeeinflusszone

- Laserauftragschweißen mit lokalisierter Erwärmung, geringer Verformung des Substrats, geeignet für die Bearbeitung von Präzisionsteilen.

4. Metallurgische Bindung

- Metallurgische Verbindung zwischen der Plattierungsschicht und dem Grundmaterial, hohe Haftfestigkeit, Vermeidung von Delaminations- oder Ablöseproblemen.

5. Reparatur und Verstärkung

- Geeignet zur Reparatur verschlissener oder beschädigter hochwertiger Teile, wie z. B. Formen, Lager, Motorteile usw.

IV. Anwendungsgebiete

•Formenherstellung und -reparatur

•Luft- und Raumfahrt

•Automobilindustrie

•Petrochemische Industrie

•Schwere Maschinen

V. Wichtige Punkte für die Geräteauswahl

1. Laserleistungsanforderungen

- Dünnschichtverkleidung:500 W - 2 kW

- Dickschichtschweißen:3 kW-10 kW

2. Bearbeitungsgenauigkeit

- Wenn hohe Präzision erforderlich ist, wählen Sie die Ausrüstung, die mit einem geschlossenen Regelkreis ausgestattet ist.

3. Art des Schmelzmaterials

- Je nach Werkstoff des Werkstücks und Einsatzumgebung ist das geeignete Pulver- oder Drahtzuführungssystem auszuwählen.

4. Arbeitsbereich und Flexibilität

- Sicherstellen, dass der Bewegungsbereich des Gerätetisches oder des Roboterarms den Produktionsanforderungen entspricht.

VI. Der zukünftige Entwicklungstrend

1. Intelligente Steuerung

- Integration von künstlicher Intelligenz und maschinellem Lernen zur Optimierung der Parameter des Beschichtungsprozesses und zur Verbesserung der Verarbeitungsqualität.

2. Verbundfassadentechnologie

- Entwicklung von mehrschichtigen Verbundwerkstoffverkleidungen zur Erfüllung höherer Leistungsanforderungen.

3. Umweltschutz und Energieeinsparung

- Entwicklung eines effizienteren und energieärmeren Laserauftragschweißsystems zur Reduzierung des Ressourcenverbrauchs.

Automatische Laserauftragschweiß- und -beschichtungsanlagenist ein wichtiges technisches Werkzeug in der modernen Fertigungsindustrie, das aufgrund seiner hohen Präzision, Automatisierung und Materialverträglichkeit in verschiedenen High-End-Fertigungs- und Reparaturbereichen weit verbreitet eingesetzt wird.

Veröffentlichungsdatum: 02.12.2024